Waterjet cutting FAQ

Learn more about waterjet cutting

Waterjet cutting is a versatile and efficient method for cutting a wide variety of materials with high precision. Here are some frequently asked questions to help you understand the benefits, applications, and technology behind waterjet cutting. Discover how this environmentally friendly and accurate cutting method can enhance your manufacturing processes and improve productivity.

WATER JET CUTTING PROCESS

How does waterjet cutting work?

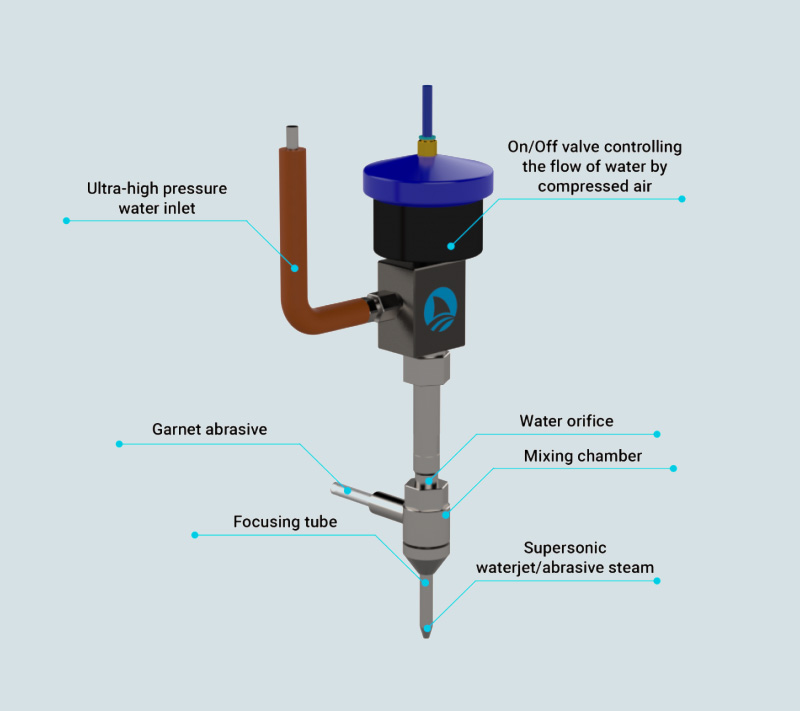

A waterjet cutting machine, also known as a water jet cutter or water jet, is an industrial cutting tool capable of cutting a wide variety of materials practically in any form. It is a non-thermal cutting method that is based on a high velocity of a waterjet.

Water is pressured into extremely high pressure (up to 6200 bar) and this jet is focused on the material that needs to be cut. With the power of erosion, the jet will go through the material separating the pieces.

There are two main types of waterjet cutting: pure water cutting with only water and abrasive waterjet cutting where abrasive is mixed to the waterjet. Pure water cutting is used for softer materials such plywood, plastic, or rubber as there the waterjet has enough energy to pierce and cut the material. Adding abrasive and thus creating a mixture of abrasive and water is increasing the energy of the jet and this can be used to cut hard materials such as metals, stone, glass, or carbon fiber. Both methods can be referred as waterjet cutting.

BENEFITS OF WATERJET CUTTING

What are the benefits using waterjet?

Waterjet cutting offers a range of benefits that make it a superior choice for many industrial applications. This versatile cutting method can handle a wide variety of materials, from metals and ceramics to composites and glass, providing exceptional precision and efficiency.

Thus waterjet cutting is offering a combination of precision, efficiency, and environmental friendliness. Explore how Muototerä’s FinJet waterjet cutting machines can enhance your manufacturing processes and improve productivity. For more information or personalized advice, please contact our team.

Some key advantages of using waterjet cutting:

Virtually no material limitations, very thin and very thick materials can be cut by waterjet cutting. Common materials to cut include metals, rubbers, stone, glass, plywood, plastics, foams, textiles, foodstuff, leather, etc. This makes waterjet cutting ideal for a diverse range of industries, from aerospace to automotive, machinery, shipbuilding, construction, food product, and much more.

No material changes due to heat affect zone, no material distortion, process enabling strict tolerances. Produces smooth, burr-free edges that often require no further finishing, saving time and additional processing costs.

Minor loss of material due to effective nesting and thin cutting kerf. The narrow kerf width allows for precise cuts and intricate details, enhancing the accuracy and quality of the final product.

FinJet machines offer also wide range of unmanned cutting options thus further enhancing efficiency.

No additional finishing usually needed, cutting can be done with several cutting heads and stacked materials. Waterjet cutting can also achieve high cutting speeds, increasing productivity and efficiency in manufacturing processes. This is usually the case in softer materials.

Our advanced 5-axis and robot waterjet cutting capabilities enable the creation of complex geometries and intricate shapes, providing greater design flexibility and precision. Practically all cutting shapes are possible with 5-axis cutting or robot cutting.

Waterjet cutting uses water and abrasive materials, making it a safer and cleaner cutting method compared to other techniques that involve hazardous chemicals or materials.

Waterjet cutting is thus an environmentally friendly process, making it a green choice for industrial applications.

|

|

Laser beam | Plasma beam | |

|---|---|---|---|

| Suitable materials | All | Homogenous, no reflective bodies | Metals & conductive materials |

| Material thickness | Thick & thin | Thin & medium | Medium & thick |

| Shapes | Complicated | Complicated | Simple |

| Material hardening | No | Yes | Yes |

| Thermal deformation | No | Yes, small area | Yes, wider area |

| Hazadous vapours | No | Yes | Yes |

| Multilayer cutting | Possible | Impossible | Impossible |

| Precision cutting | High | High | Medium |

Waterjet cutting FAQ

Frequently asked questions

Waterjet cutting process

Waterjet cutting machines

Applicable Industries

Waterjet cutting solutions for different industrial sectors

The undoubted advantage of waterjet cutting is versatility. The cutting method is suitable for environmentally friendly cutting of almost all materials, such as aluminum, steel, glass, stone, plywood, rubber, plastic, foam and food.