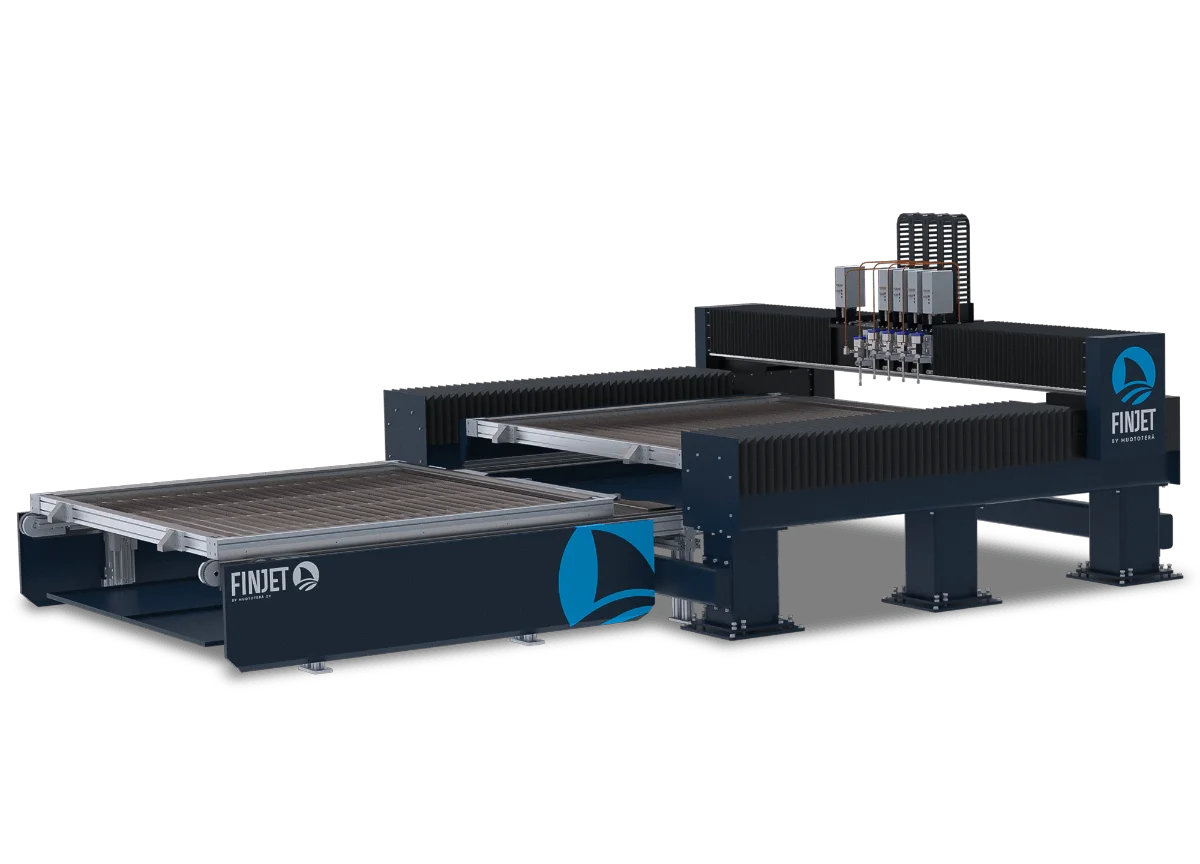

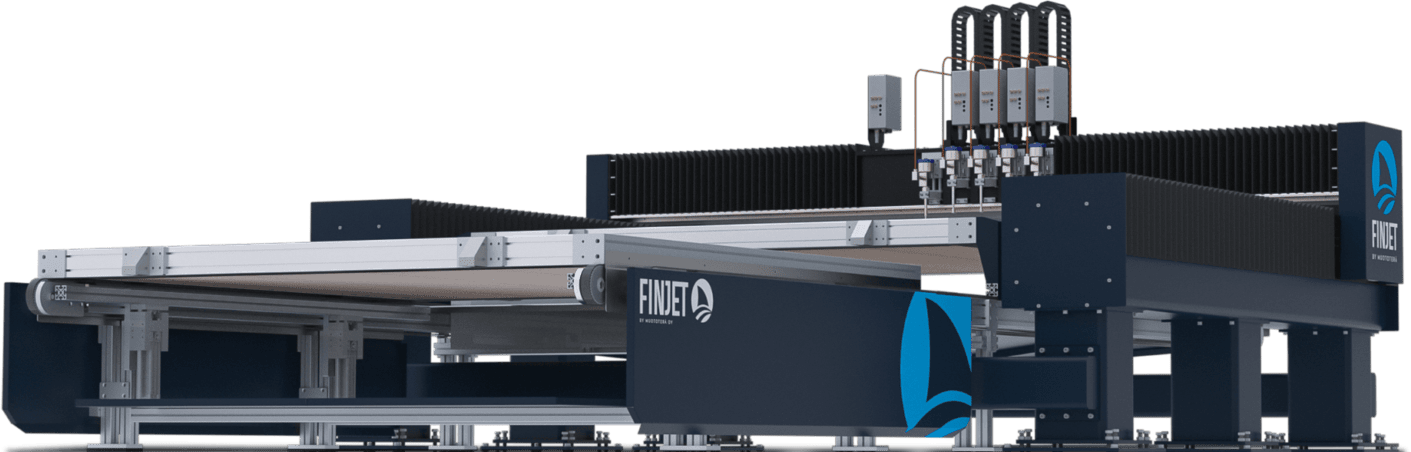

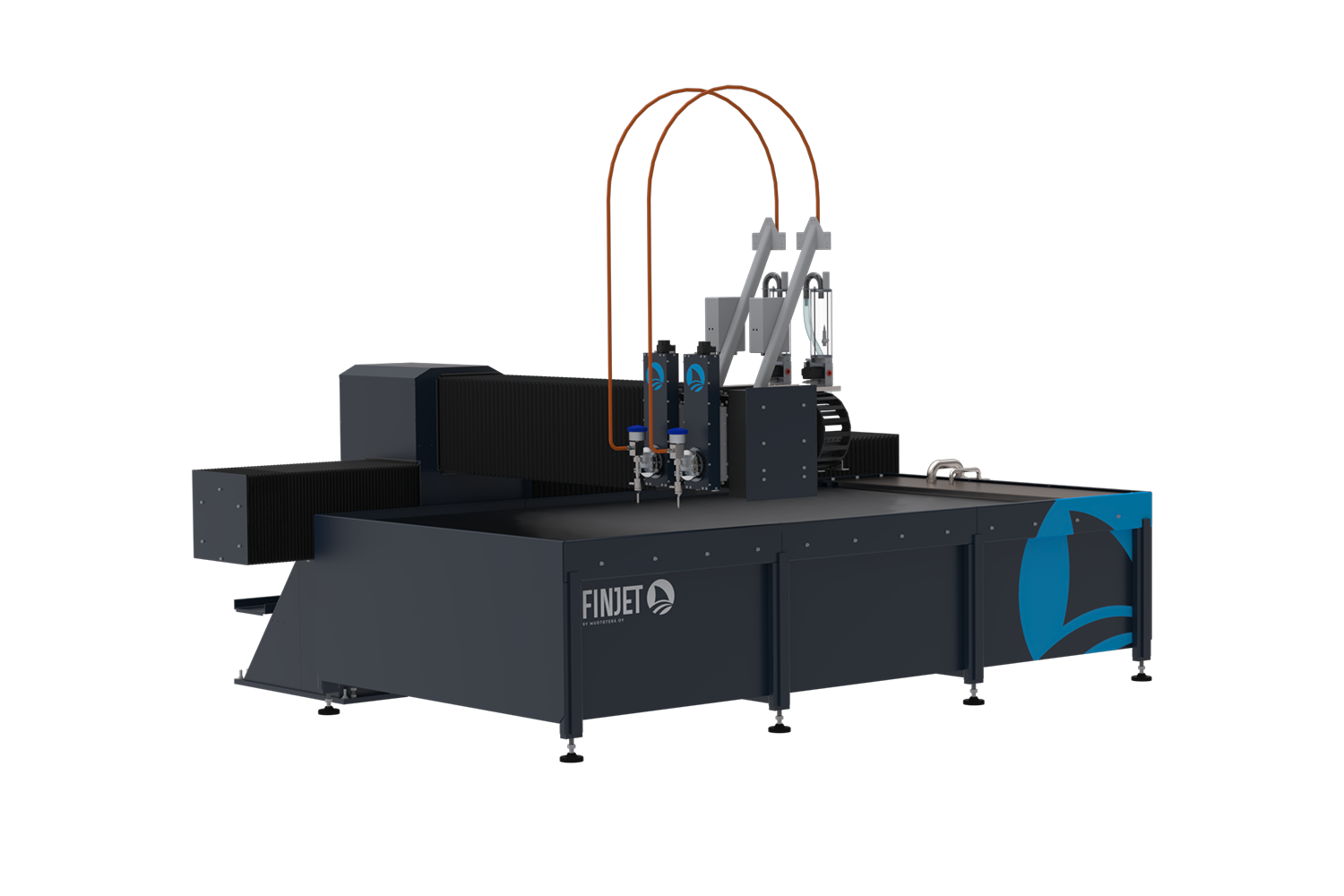

Finjet P

Technical specifications

When cutting soft materials, such as plastic, foam, rock wool, rubber or plywood, abrasive can be left out from the cutting process. This enables faster movements and system can be optimized for pure waterjet cutting.

- Cutting area: 2 x 2 – 3 x 2 m

- Z-axis: 100/ 200 / 300 mm

- Positioning accuracy: ± 0,025 mm/m

- Repeatability: ± 0,015 mm

- X and Y axis max speed: 40 / 100 m/min

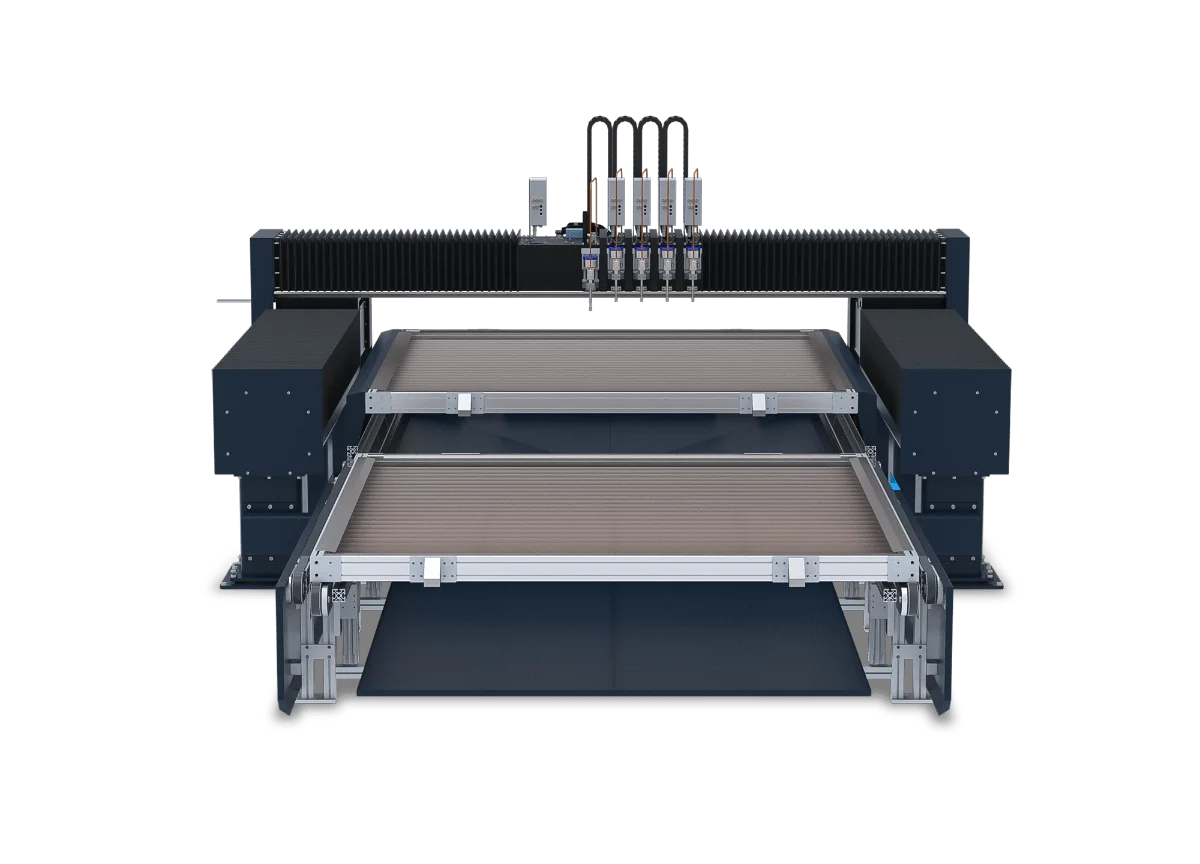

- Cutting heads: 1 – 6, 2D or 3D

The FinJet P models are powered by high-performance linear motors up to a maximum power of 7000 N, delivering speeds of 40 m/min or up to 100 m/min. In addition, there is always a separate measuring system for precision linear guides, which allows precise positioning of the machine, despite its high acceleration.

Benefits of a linear motor:

– High speeds and accelerations

– Measuring function integrated into the system

– The absolute position is always known

– High system positioning and repeatability

– Inductive non-contact measurement principle

– Good resistance to abrasion

– No worn transmission components

Since pure waterjet cutting machines are always exposed to at least water, the protection must be designed accordingly. In FinJet P models, the X-axis is always protected by a tight round bellows. The Y-movement is protected by a U-bell and the machine frame is covered to withstand extreme condition

Electric cabinets on FinJet P models are always built with closed circuit cooling, which makes electrical and automation components more durable and the water cutter less susceptible to failure. The machine is controlled by Muototerä’s own interface for water cutting. The HMI (Human Machine Interface) is a 21.5 ”Full HD touchscreen with a powerful 1.91GHz processor. The user interface has been designed based on the user experience so that it is simple yet powerful, offering all the features needed for effective waterjet cutting.

Electrical and automation design on all FinJet waterjet cutting machines is planned and executed by Muototerä’s own personnel. This allows optimum compatibility between mechanical and automation components. A good water cutting machine is made from quality components, but it is not enough on its own. All parts must work together seamlessly. The objective of Muototerä is always to make the waterjet cutting machines perform better than the sum of their parts. In practice, this means collaborative design in mechanical and automation so that they are executed simultaneously for best results.

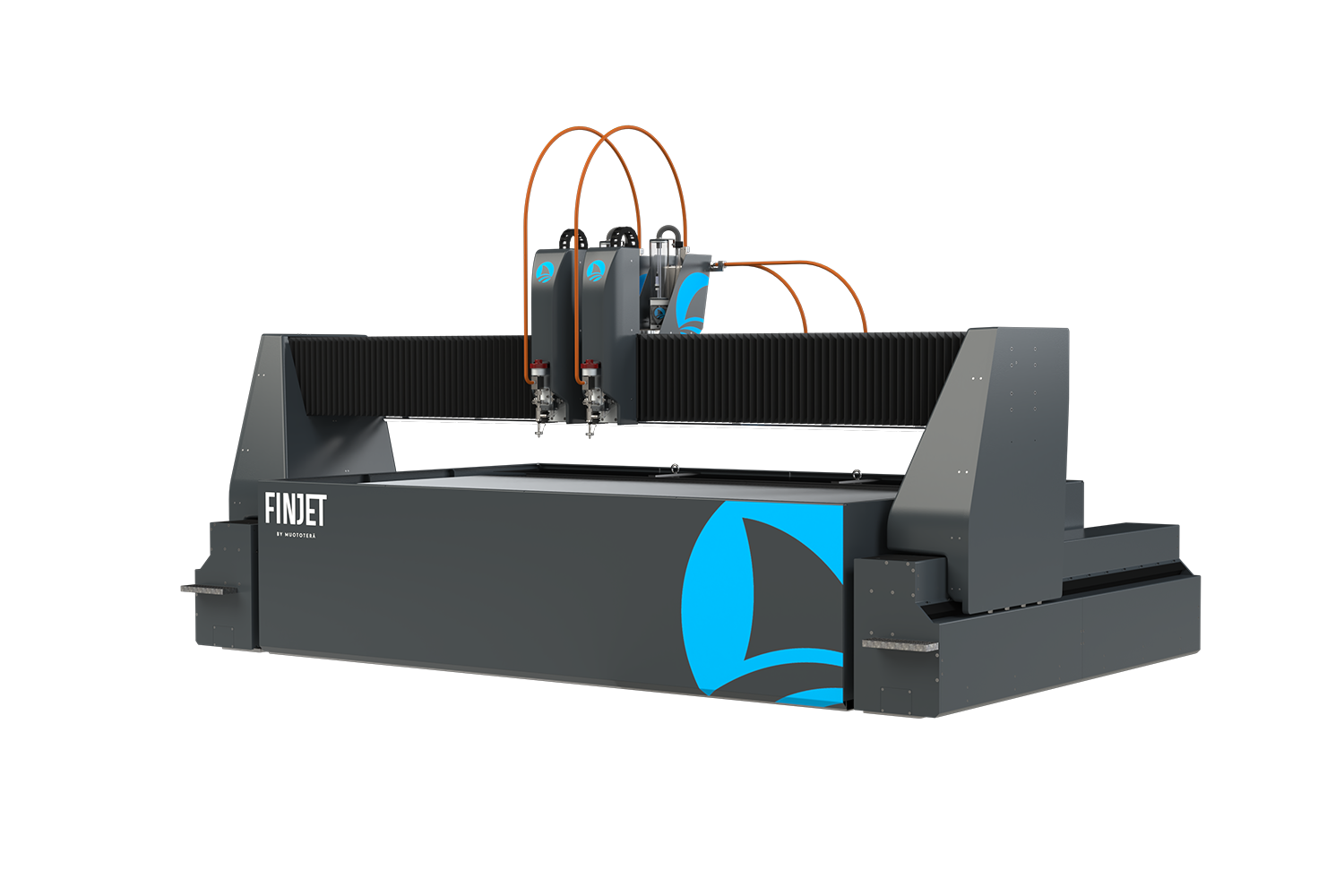

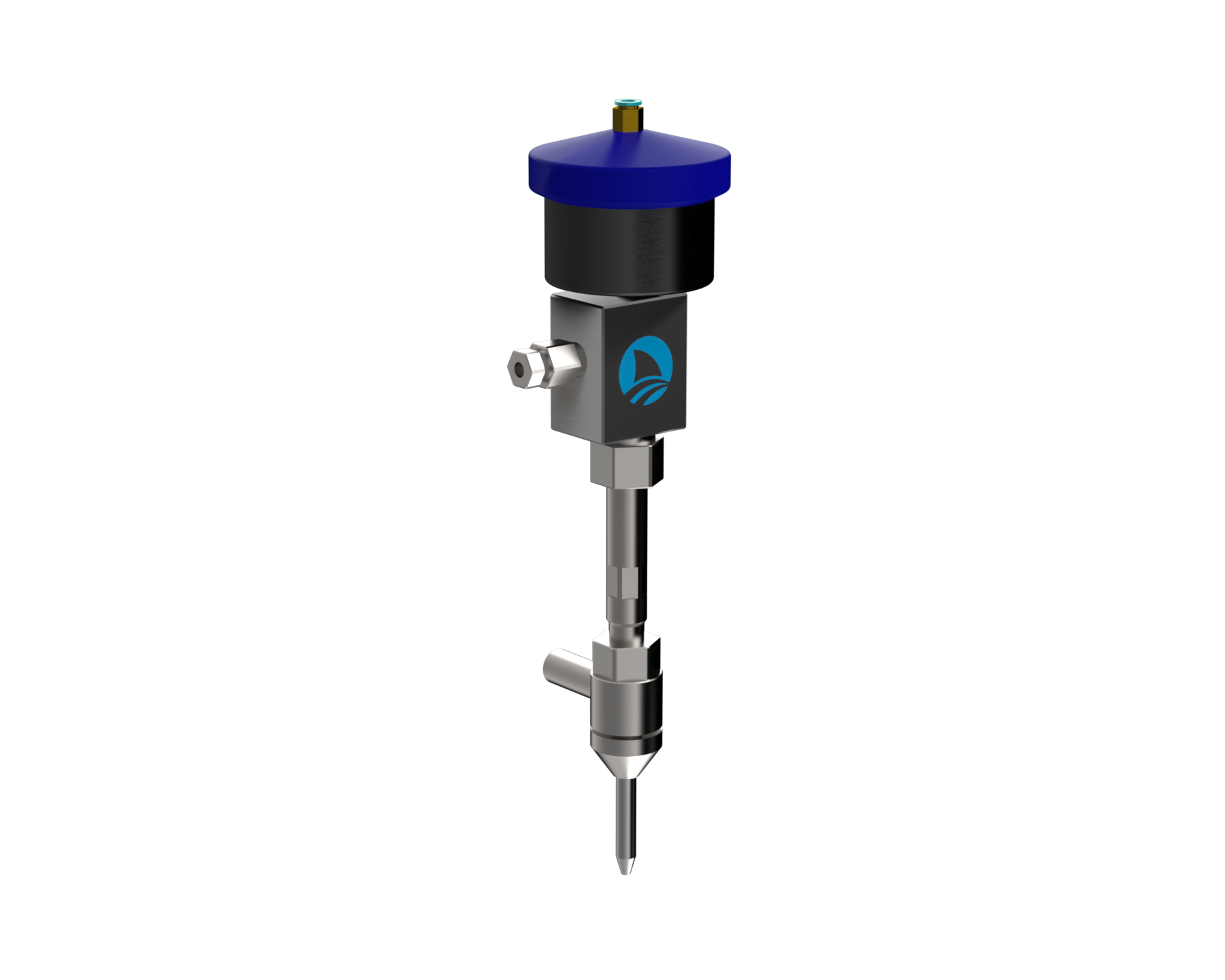

High pressure components play a critical role in waterjet cutting. As it is a high pressure device (3800 – 6200 bar), the high pressure components are subjected to extremely heavy stress. In addition to the self-made components, Muototerä uses components from KMT Waterjet. High-quality components guarantee the reliability of the machine at all pressure levels.

All FinJet waterjet cutting machines can be connected to any high-pressure pump, including old ones already at the client’s site. Muototerä is an official distributor of KMT High Pressure Pumps and a Premium OEM Partner. Our high pressure pump product range can be found here

Finjet P

Available options & accessories

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat. Duis aute irure dolor in reprehenderit in voluptate velit esse cillum dolore eu fugiat nulla pariatur. Excepteur sint occaecat cupidatat non proident, sunt in culpa qui officia deserunt mollit anim id est laborum. sunt in culpa qui officia

Cutting head

Control & machine

High preassure pump accessories

Cutting tank

Safety

Applicable Industries

Waterjet cutting solutions for different industrial sectors

The undoubted advantage of waterjet cutting is versatility. The cutting method is suitable for environmentally friendly cutting of almost all materials, such as aluminum, steel, glass, stone, plywood, rubber, plastic, foam and food.

The operation model form Muototerä is based on fast, reliable and flexible service. We are always customer-oriented, which means that we can provide you with the service concept that suits you. So we’re not trying to get our clients in the same mold, but tailor our services according to needs.

H

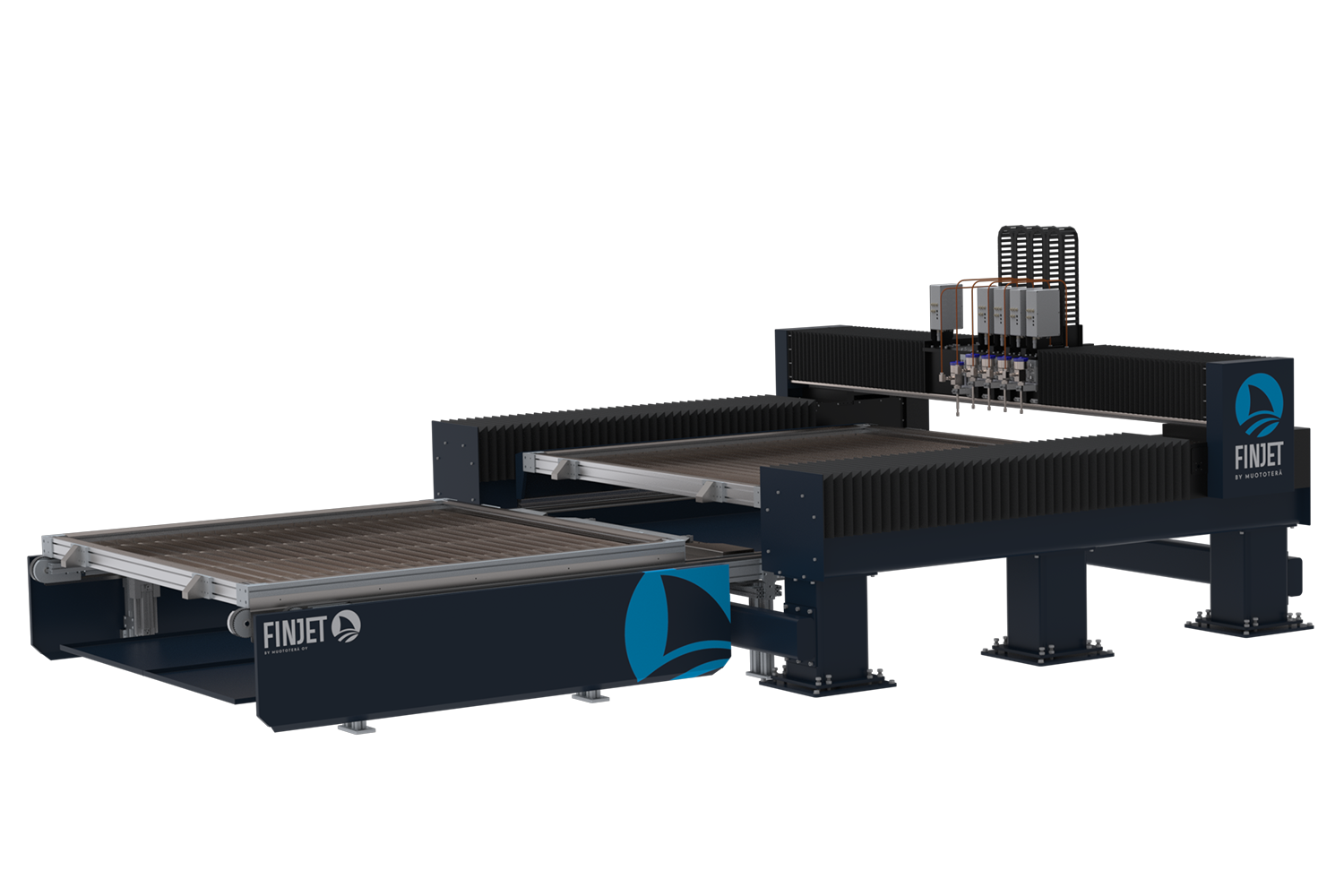

Portal Waterjet Cutting Machine

FinJet H-series is designed for continuous heavy duty waterjet cutting. Its modular portal design enables numerous different variations so that every demanding need can be fulfilled. H-series can be equipped with several cutting heads including 5- axis bevel cutting units.

L

Flying Bridge Waterjet Cutting Machine

FinJet L-series is designed for flexible cutting in all environments. Flying bridge design enables the effective use of the machine from three different sides. No matter if you are running a small job shop or producing demanding parts 24/7, with L-series you will be able to correspond all needs of waterjet cutting.

P

Pure Waterjet Cutting Machine

When cutting soft materials, such as plastic, foam, rock wool, rubber or plywood, abrasive can be left out from the cutting process. This enables faster movements and system can be optimized for pure waterjet cutting.

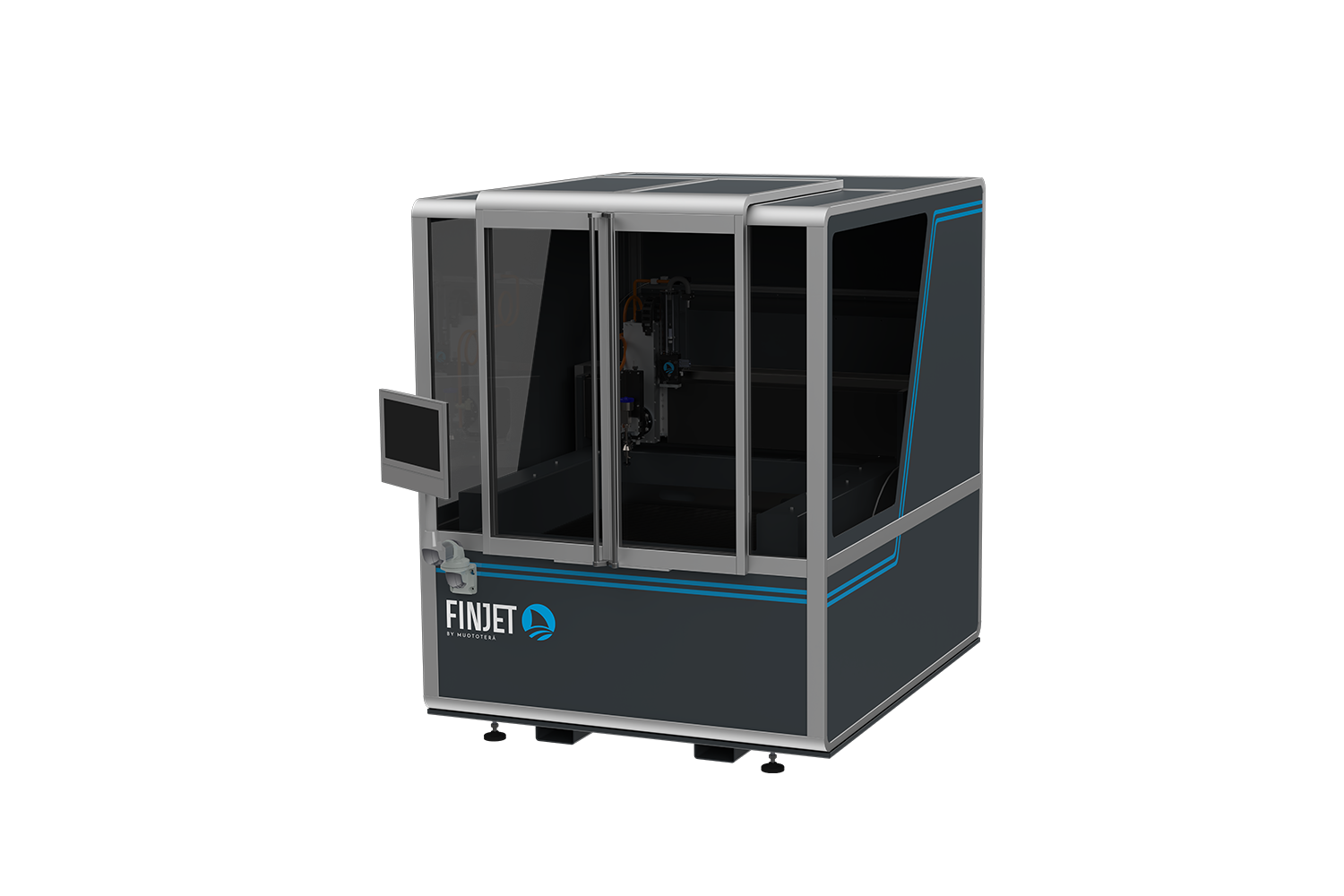

S

Compact & Capsulated Waterjet Cutting Machine

This is a plug-and-play waterjet cutting machine for quick installation and commissioning. Despite its small size, it is a compact waterjet machine for demanding cutting applications, based on the FinJet H Series.

R

Robot Waterjet System

FinJet R-series covers wide range of robot integrated waterjet cutting systems. Waterjet robot is ideal solution when we are aiming for maximum automation of the cutting process. FinJet R series is available for both water-only and abrasive waterjet cutting.

X

Client Customized Cutting System

Sometimes the cutting need is so exotic or demanding that normal waterjet cutting machines cannot offer the best solution. In this case, we make plan how to solve this. FinJet X offers a turnkey package: we plan and offer to solve the problem through the expertise brought by the experience.