Chip classifiers

Make every chip count

Muototerä provides chip classifiers and analyzers to pulp and sawmill industries. When reliable particle-size analysis with very low maintenance and you

FinScreen chip classifiers allows you to analyze product deviation frequently, flexibly, and reliably. This helps to eliminate operator error and bias and ensures that you get what you pay for.

In our product range, we have manual & automated wood chip classification analyzers. Manual analyzers give accurate results and are often used in wood chip handling terminals and production sites.

Chip screening process can be semi automized with a weighting unit. With this unit, operator does not have to manually track the results, but they can be automatically transfer to an existing ERP software.

Automated classification analyzer works independently and unmanned. It enables 24/7 chip screening and analyzing. Robot is replacing the manpower and operator needs only to make sure that there are enough samples in the que.

Screening principle is based on a 120 mm stroke. The frequency is 160 cycles per minute.

Chip classification analyzer

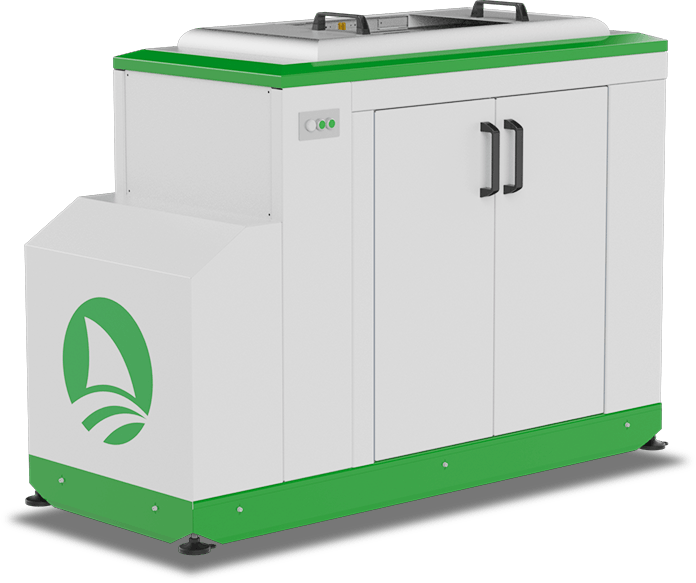

Weighting unit

This weighting unit takes the conventional chip classifying to the next level. It can be used as an extension to manual chip classifier or as a stand-alone system. Together with Muototerä’s chip classifier FinScreen, it will automatically identify screening plates and thus minimize the human error in result tracking. You can get a report in a paper and electric form.

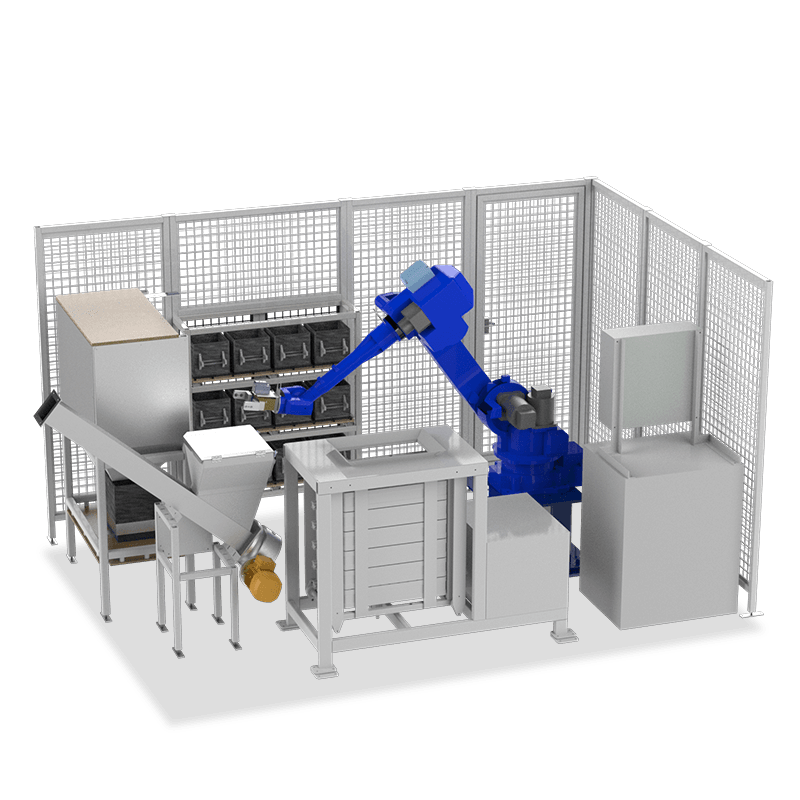

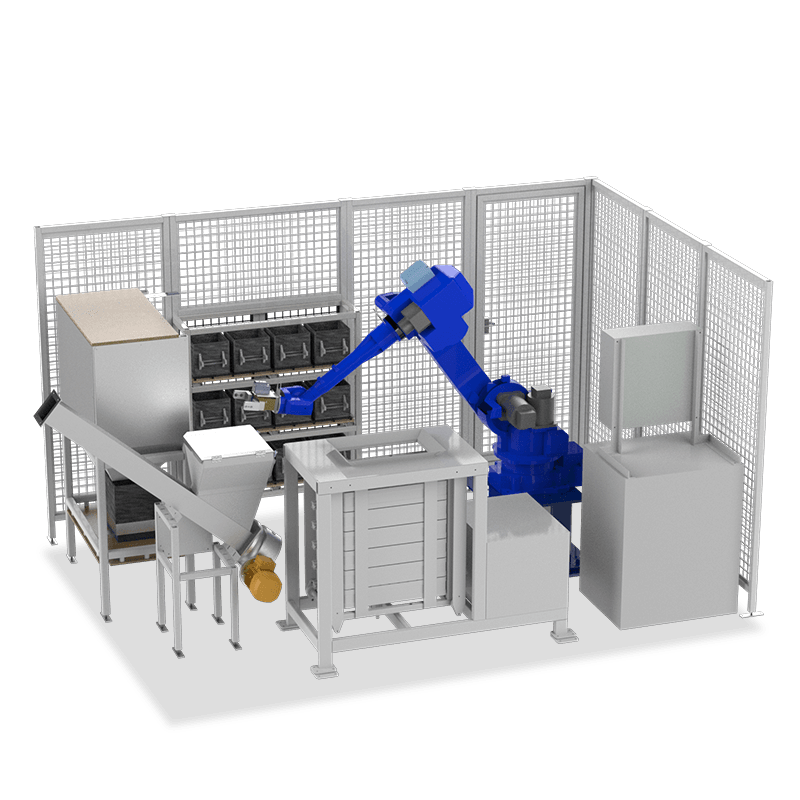

Automated robot cell

An automated robotic system to screen and analyze wood chips in a pulp, paper and sawmill industries. Main purpose is to ensure quality compliance. The automated chip classifier stores 15 samples of wood chips and screens these on its own. You can change the screening order of samples and add or remove samples during operation.

Finscreen

Frequently asked questions

Chip classifiers are particle size analyzers that provides data on wood chip sample deviation. It screens and analyses the wood chip particle distribution.

In chemical pulping process the particle size is important, because homogeneous wood chips enable:

– Standardization of the production process

– Predefined cooking time and additive chemical

– Energy need according to recipe

Even quality with repeatable process and predictable costs