S

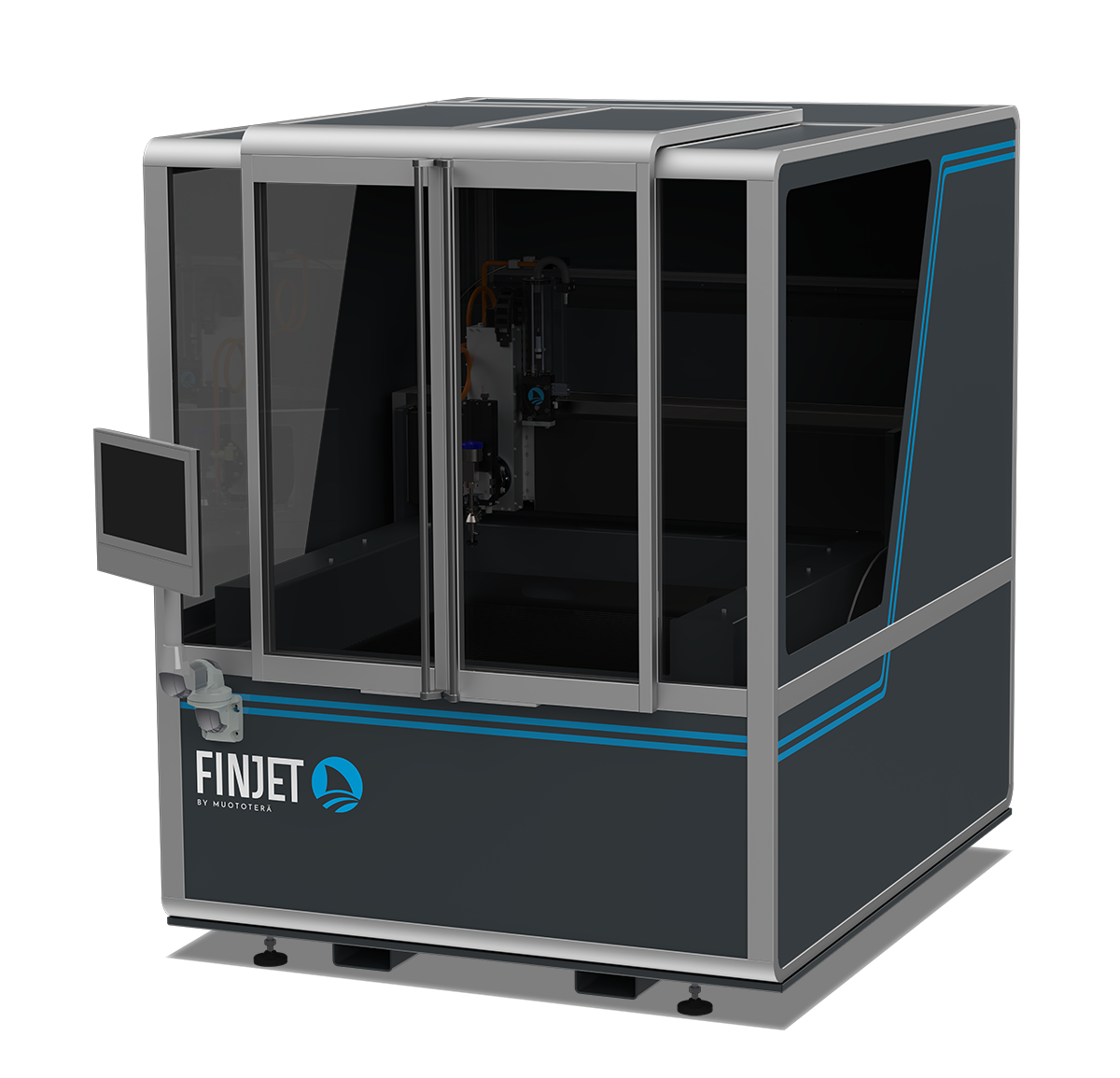

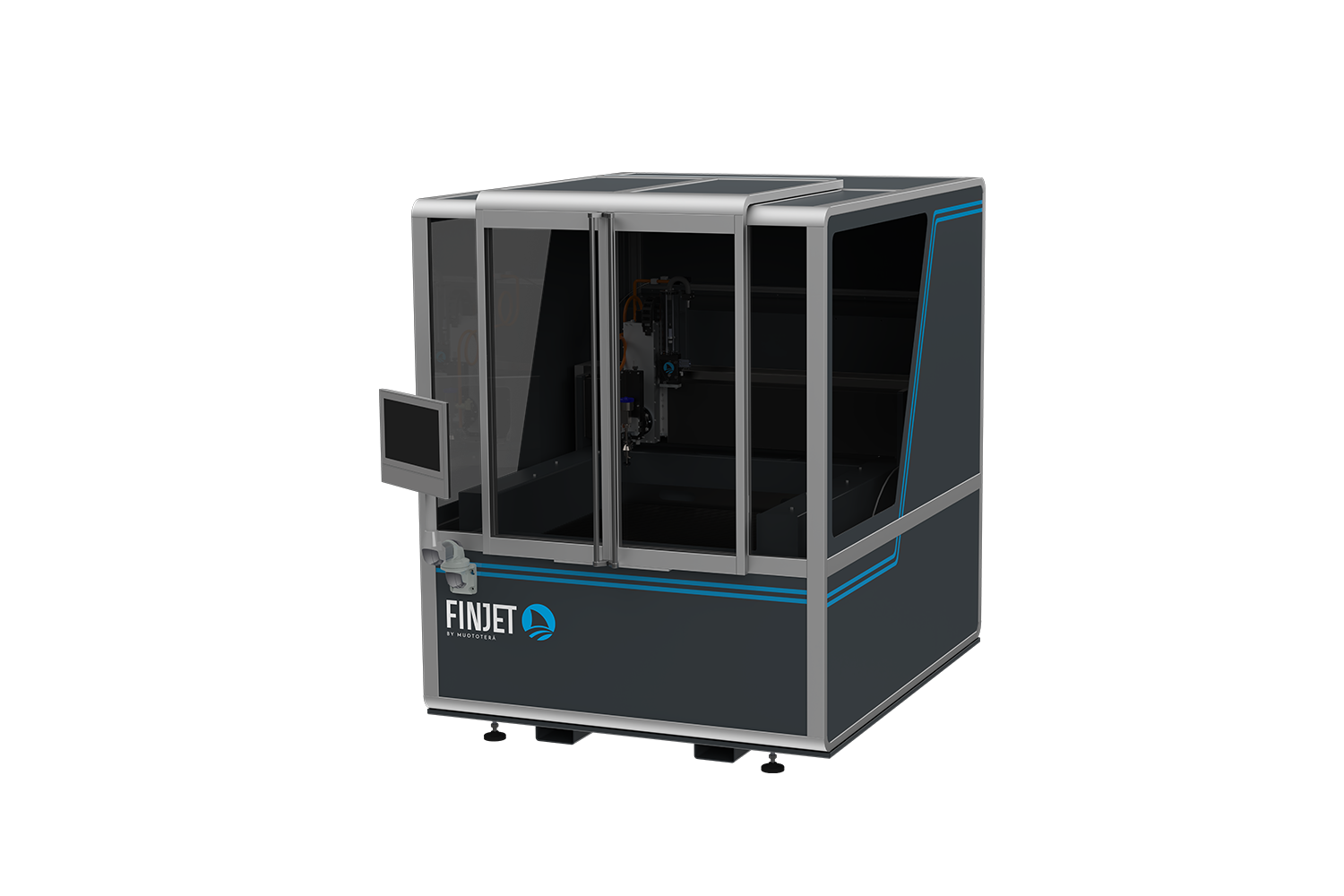

Compact & capsulated waterjet cutting machine

Finjet S

Technical specifications

Despite its small size, it is a compact waterjet machine for demanding cutting applications, based on the FinJet H Series.

- Machine dimensions without high pressure pump: width 1950 mm; depth 2500 mm; height 2400 mm

- Cutting area 1030 x 1030 mm

- Z-axis height: 200 mm

- Positioning accuracy: ± 0.025 mm / m

- Repeat accuracy: ± 0.015 mm

- Maximum speeds for X and Y axles: 15 m / min

- Waterjet cutting heads: 1

Finjet S

Available options & accessories

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat. Duis aute irure dolor in reprehenderit in voluptate velit esse cillum dolore eu fugiat nulla pariatur. Excepteur sint occaecat cupidatat non proident, sunt in culpa qui officia deserunt mollit anim id est laborum. sunt in culpa qui officia

Standard machine features

- Fully enclosed waterjet cutting machine with LED lighting inside

- Water level adjustment to allow underwater cutting

- Central lubrication points in one place

- Integrated electrical cabinet

- Integrated 50 kg cutting abrasive container

- Provision for external waste disposal system

- Operator panel integrated on the machine

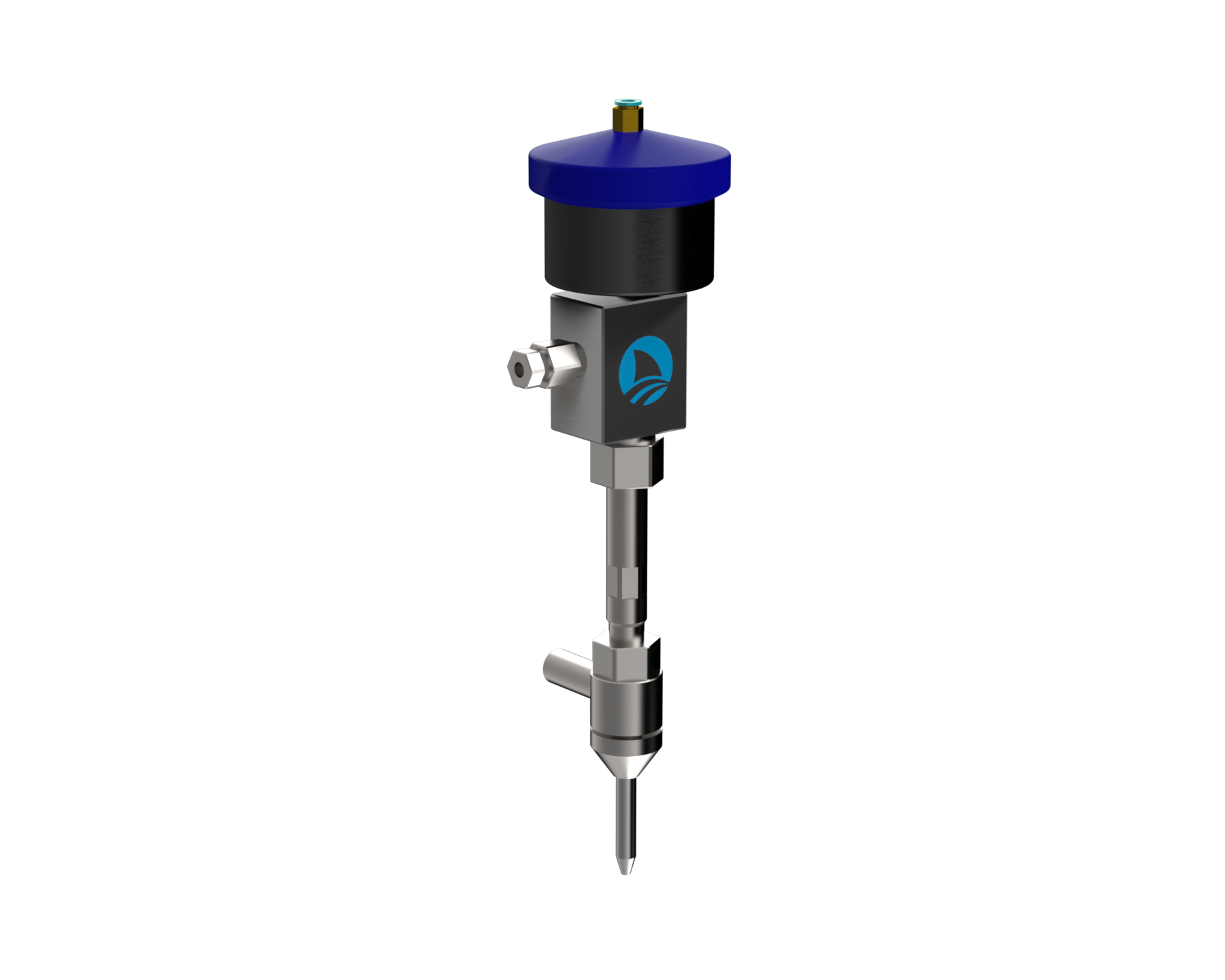

Cutting head features

- KMT IDE (integrated diamond) waterjet cutting orifice

- Height Sensor

- Infinitely adjustable abrasive feed rate of 0-600 g / min

- Sapphire crystal protected laser pointer for zero point setting

Applicable Industries

Waterjet cutting solutions for different industrial sectors

The undoubted advantage of waterjet cutting is versatility. The cutting method is suitable for environmentally friendly cutting of almost all materials, such as aluminum, steel, glass, stone, plywood, rubber, plastic, foam and food.

Despite its small size, it is a compact waterjet machine for demanding cutting applications, based on the FinJet H Series.

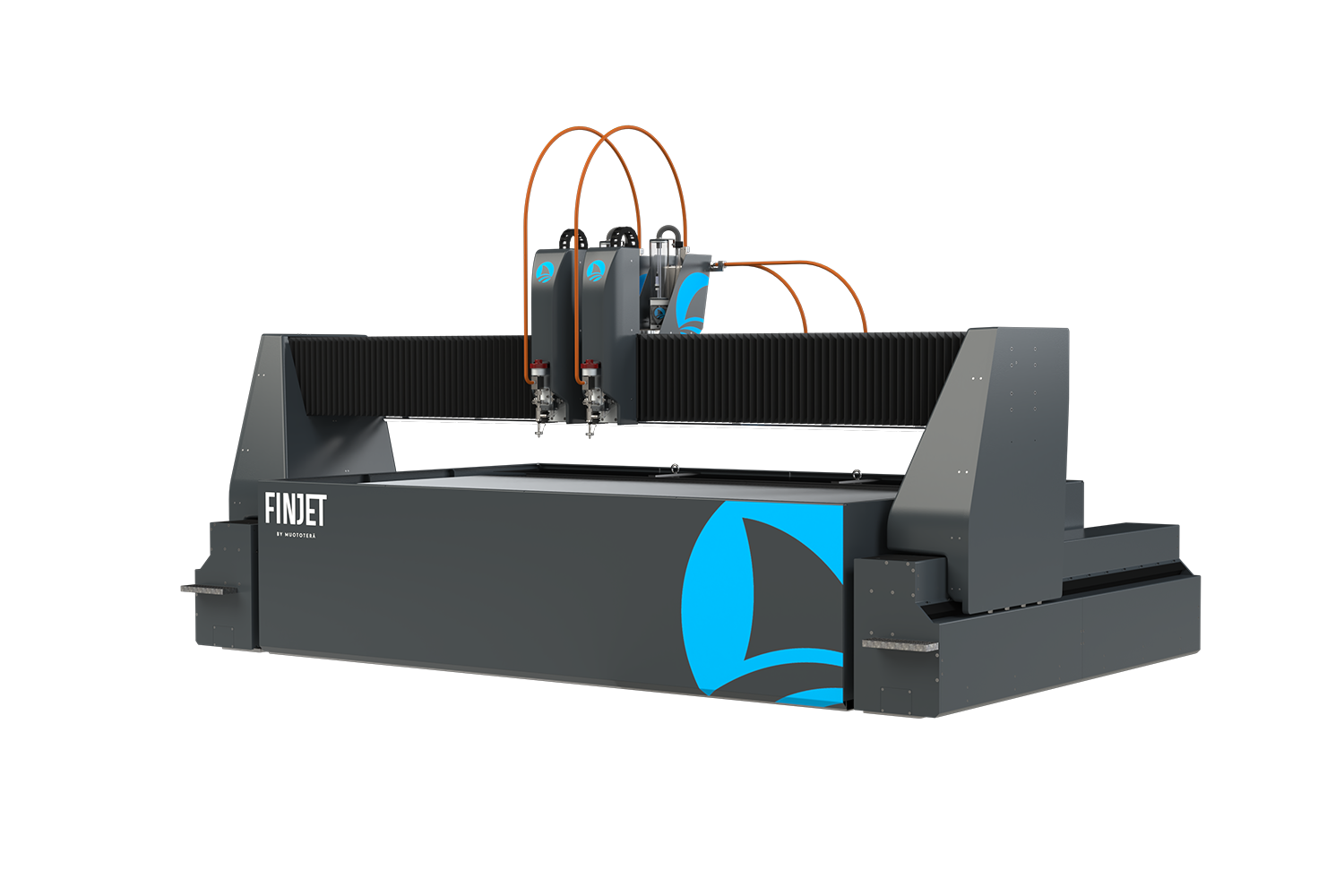

H

Portal Waterjet Cutting Machine

FinJet H-series is designed for continuous heavy duty waterjet cutting. Its modular portal design enables numerous different variations so that every demanding need can be fulfilled. H-series can be equipped with several cutting heads including 5- axis bevel cutting units.

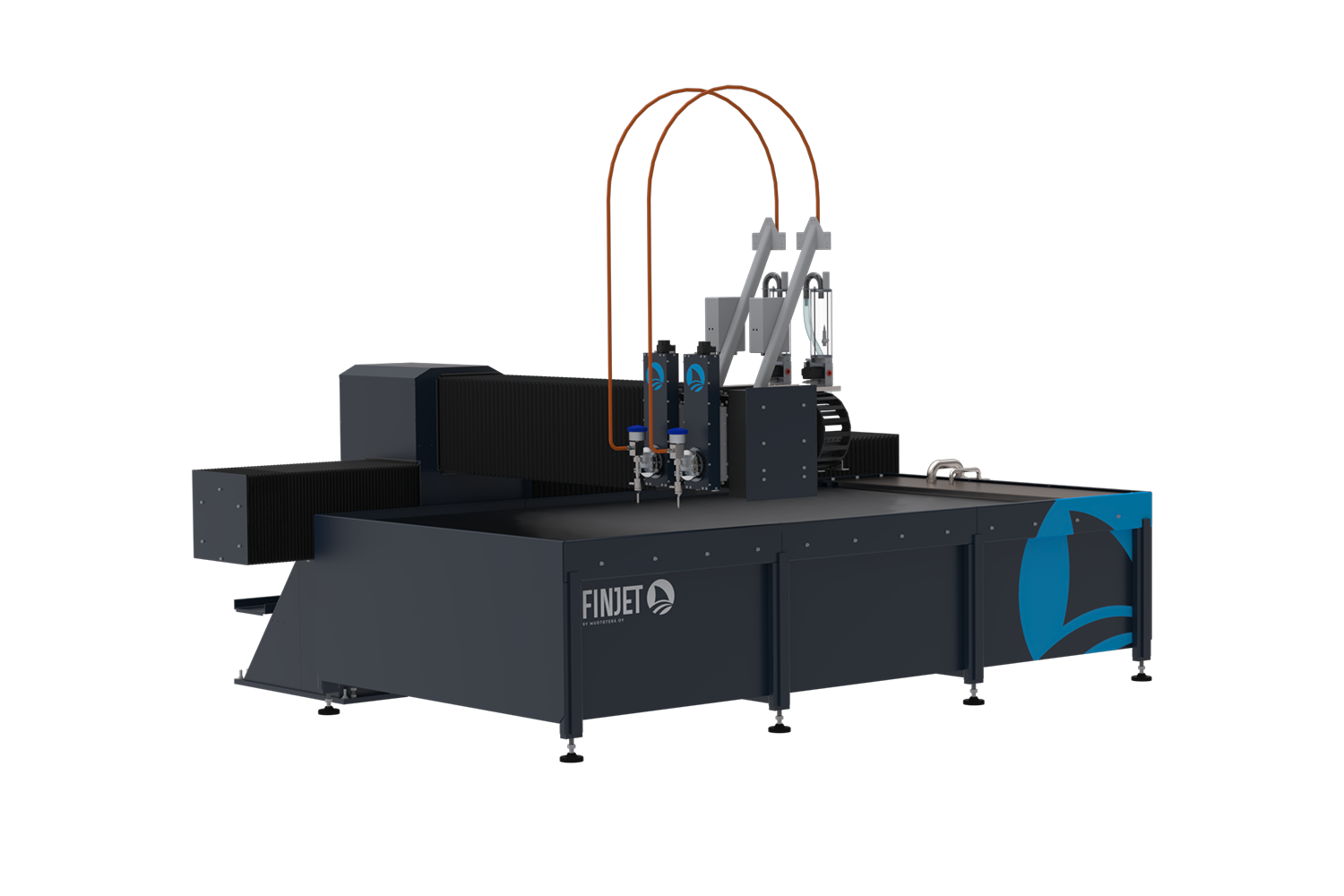

L

Flying Bridge Waterjet Cutting Machine

FinJet L-series is designed for flexible cutting in all environments. Flying bridge design enables the effective use of the machine from three different sides. No matter if you are running a small job shop or producing demanding parts 24/7, with L-series you will be able to correspond all needs of waterjet cutting.

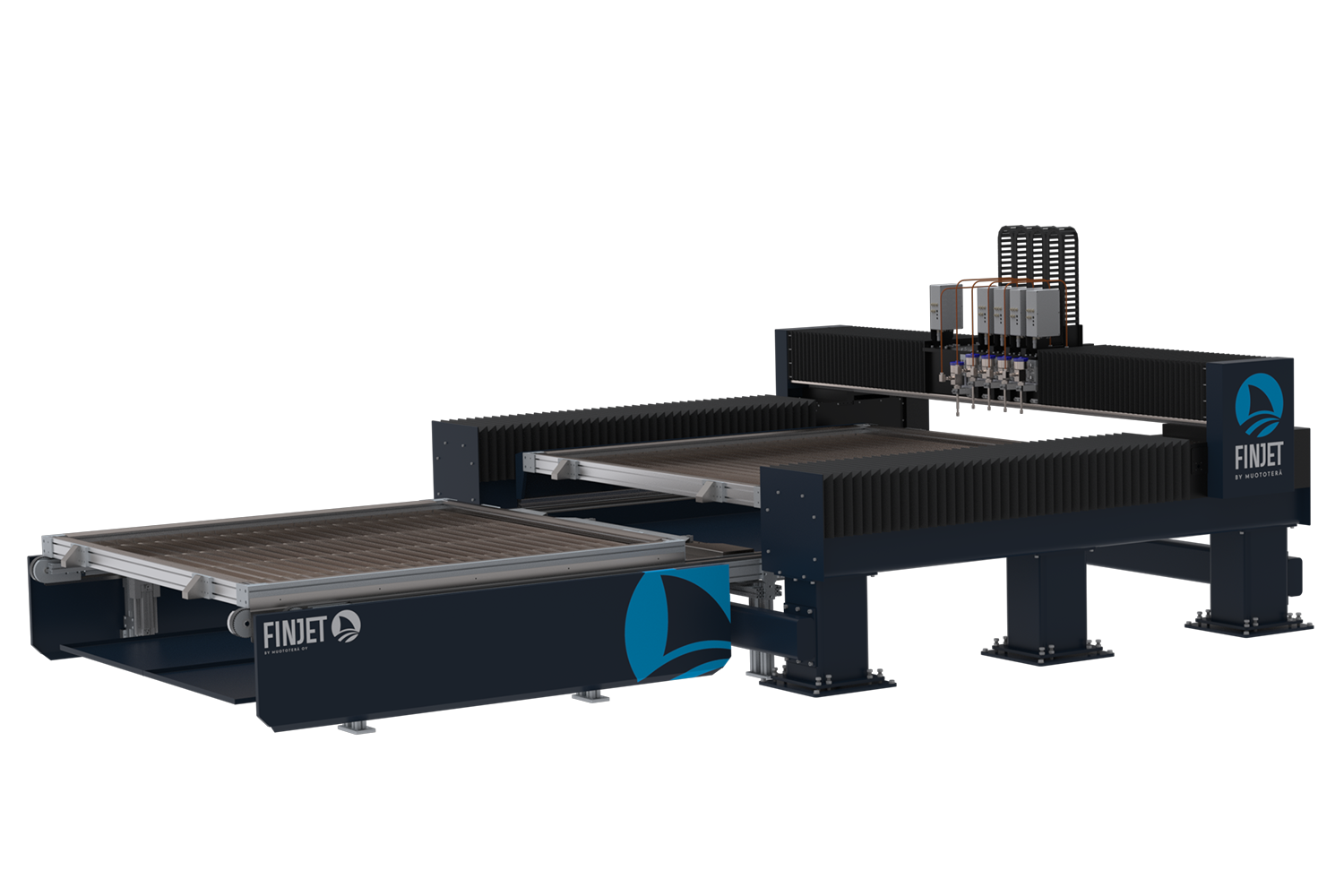

P

Pure Waterjet Cutting Machine

When cutting soft materials, such as plastic, foam, rock wool, rubber or plywood, abrasive can be left out from the cutting process. This enables faster movements and system can be optimized for pure waterjet cutting.

S

Compact & Capsulated Waterjet Cutting Machine

This is a plug-and-play waterjet cutting machine for quick installation and commissioning. Despite its small size, it is a compact waterjet machine for demanding cutting applications, based on the FinJet H Series.

R

Robot Waterjet System

FinJet R-series covers wide range of robot integrated waterjet cutting systems. Waterjet robot is ideal solution when we are aiming for maximum automation of the cutting process. FinJet R series is available for both water-only and abrasive waterjet cutting.

X

Client Customized Cutting System

Sometimes the cutting need is so exotic or demanding that normal waterjet cutting machines cannot offer the best solution. In this case, we make plan how to solve this. FinJet X offers a turnkey package: we plan and offer to solve the problem through the expertise brought by the experience.