H

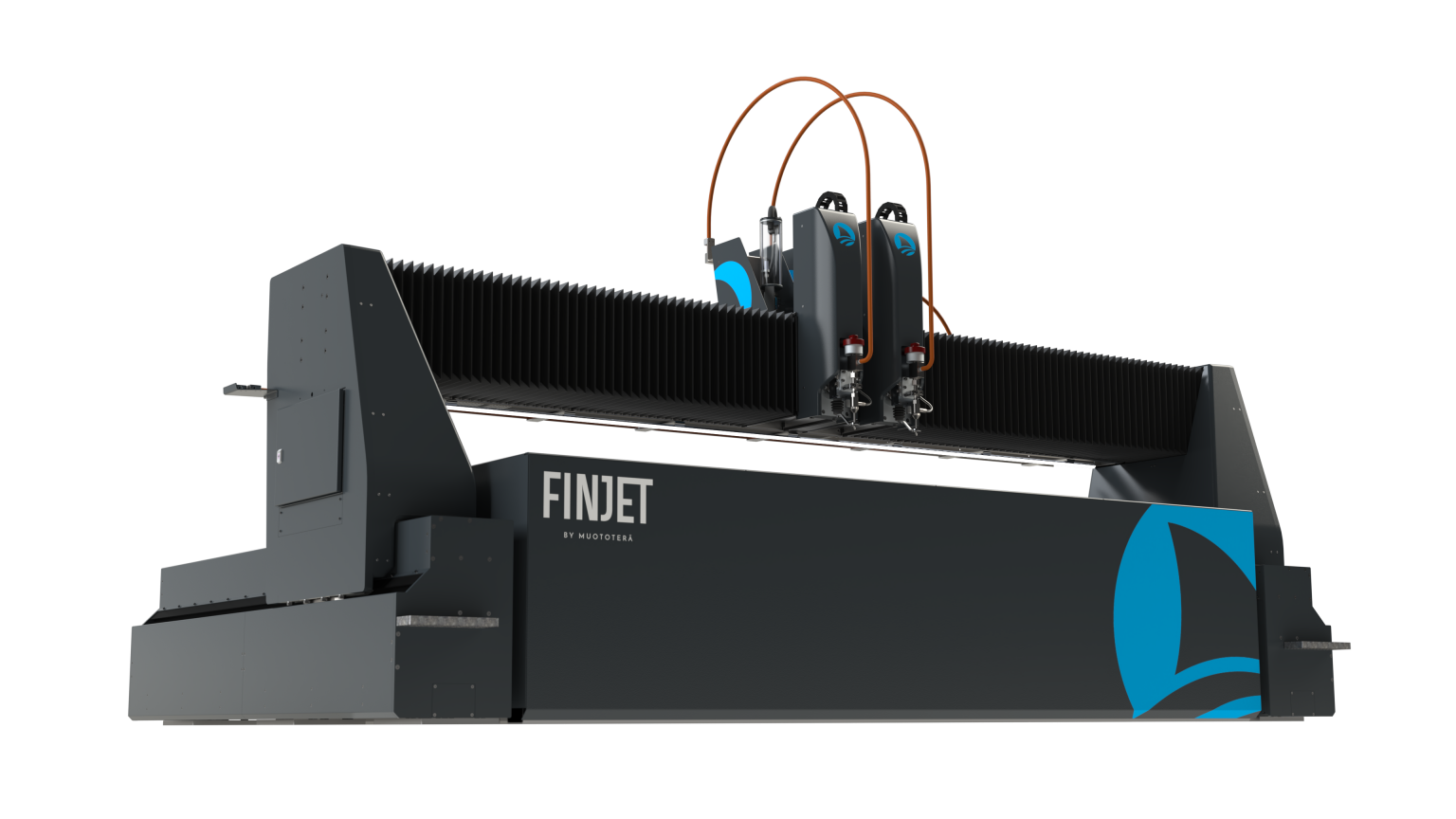

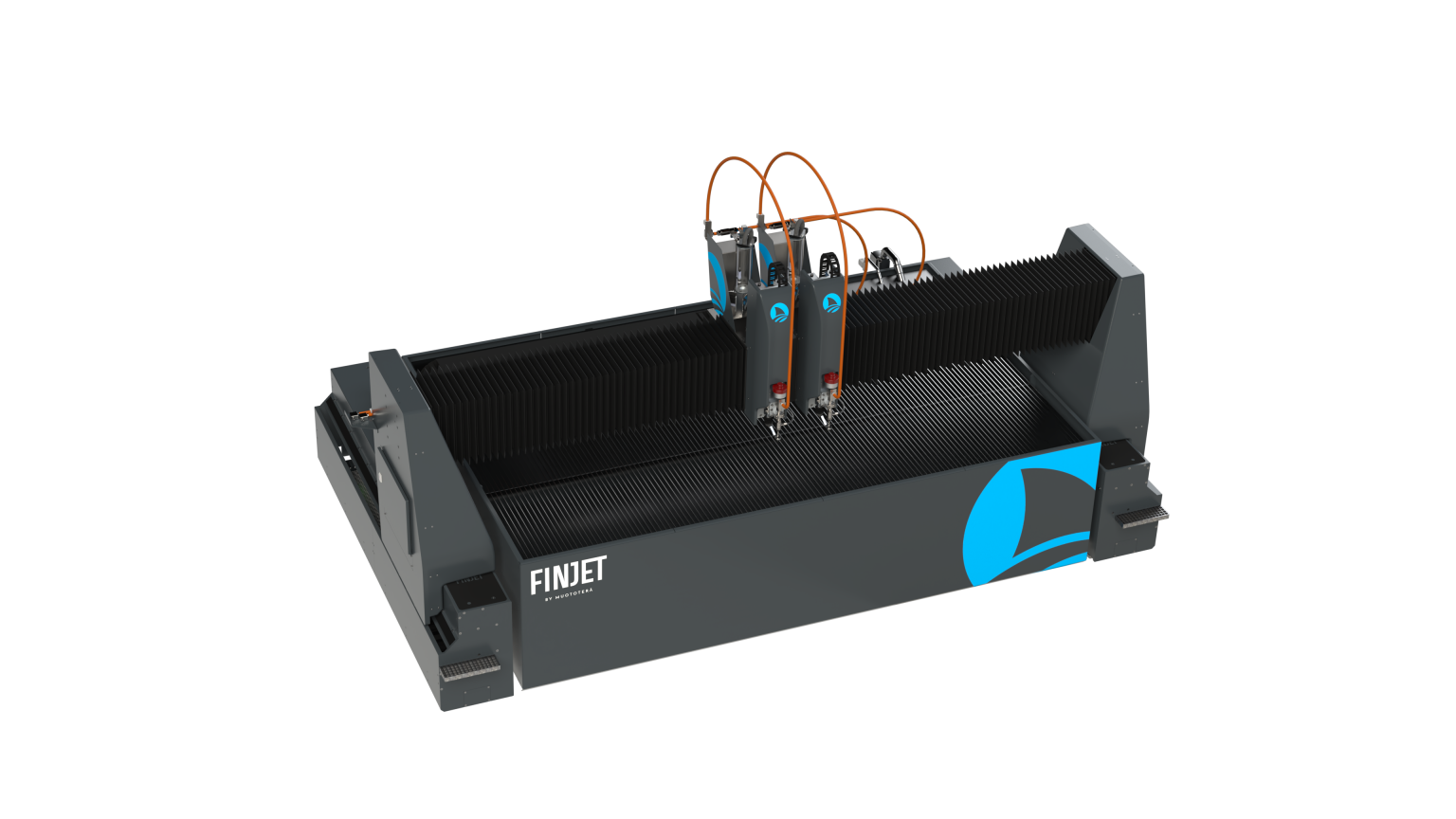

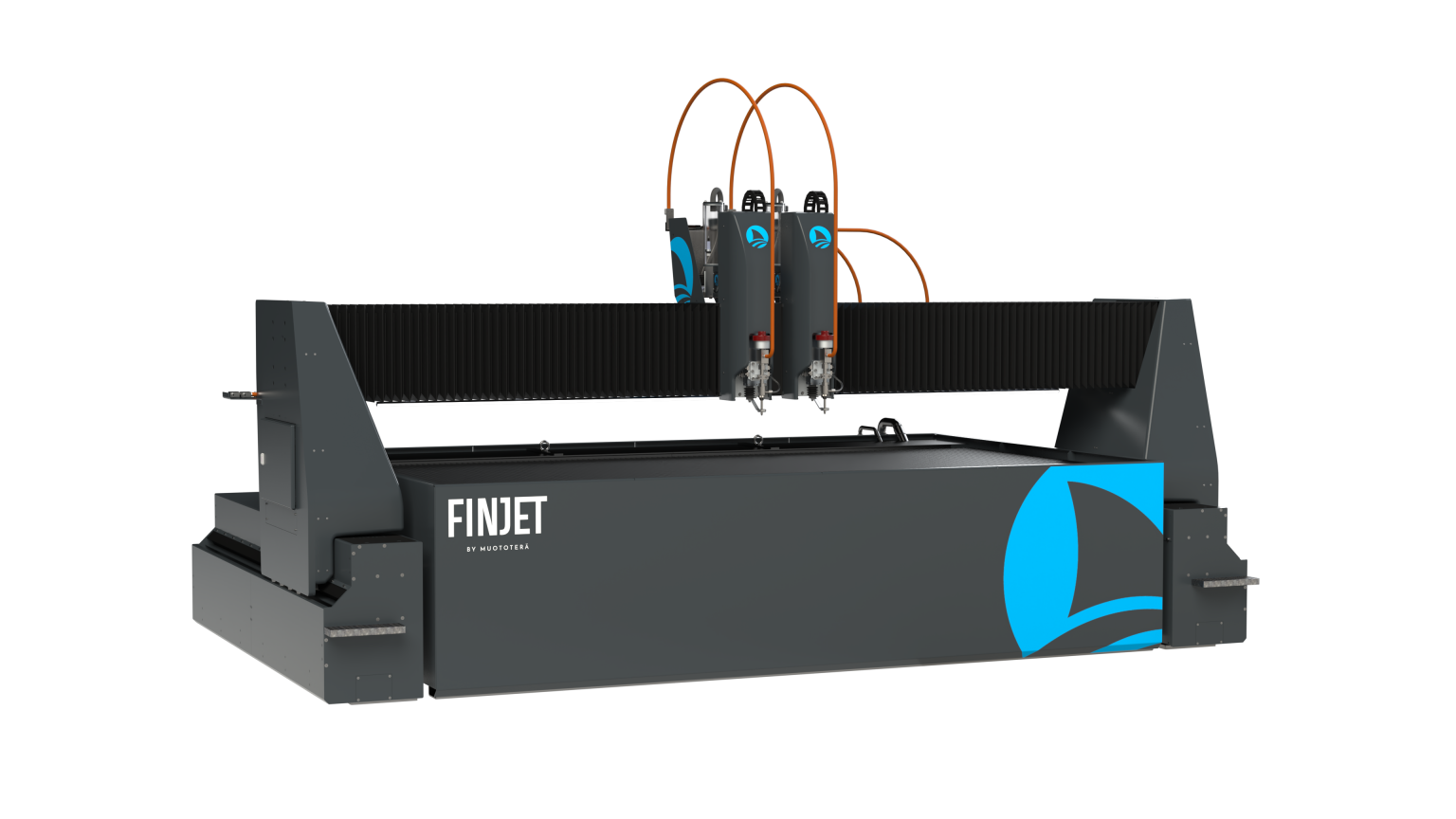

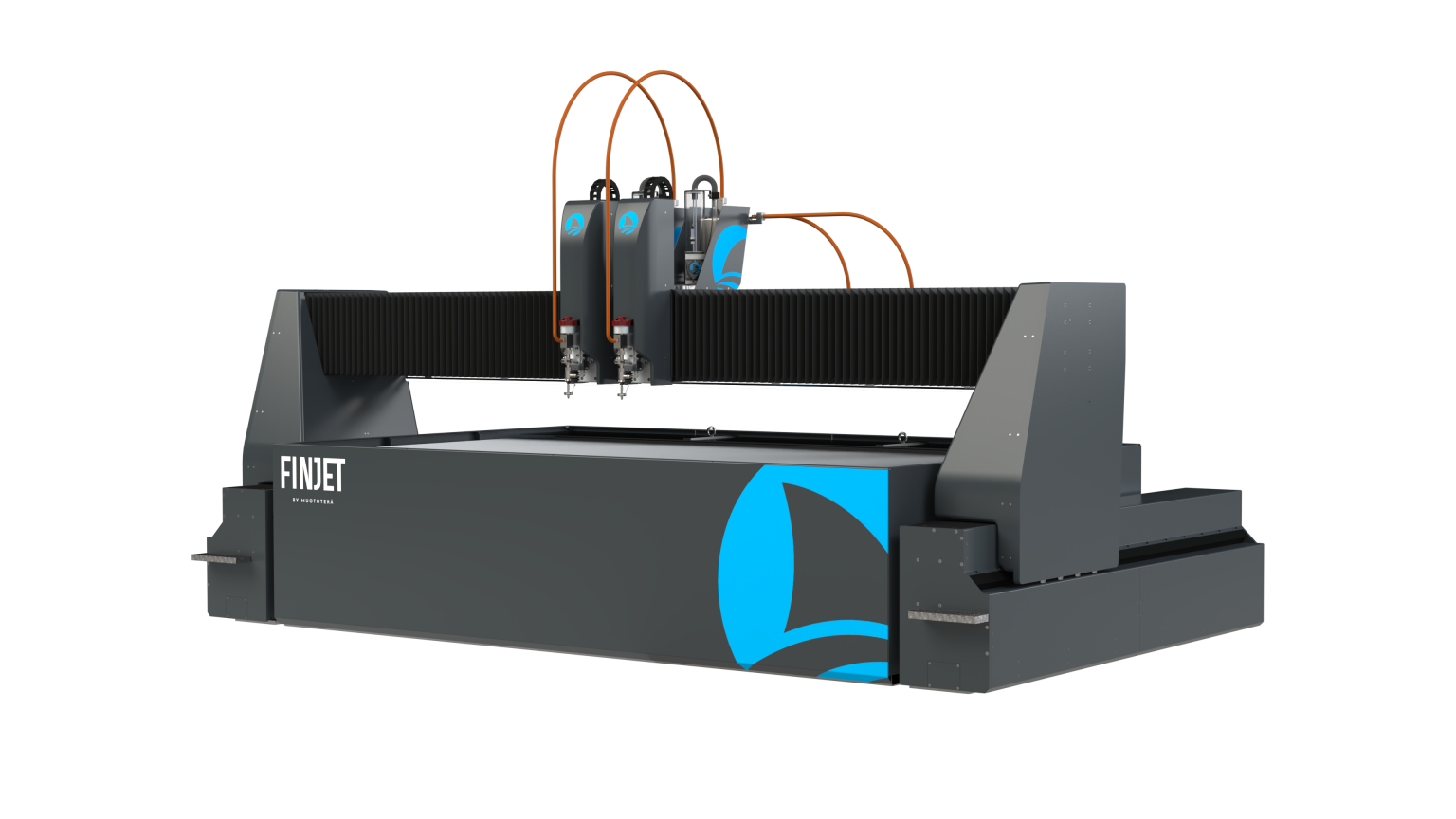

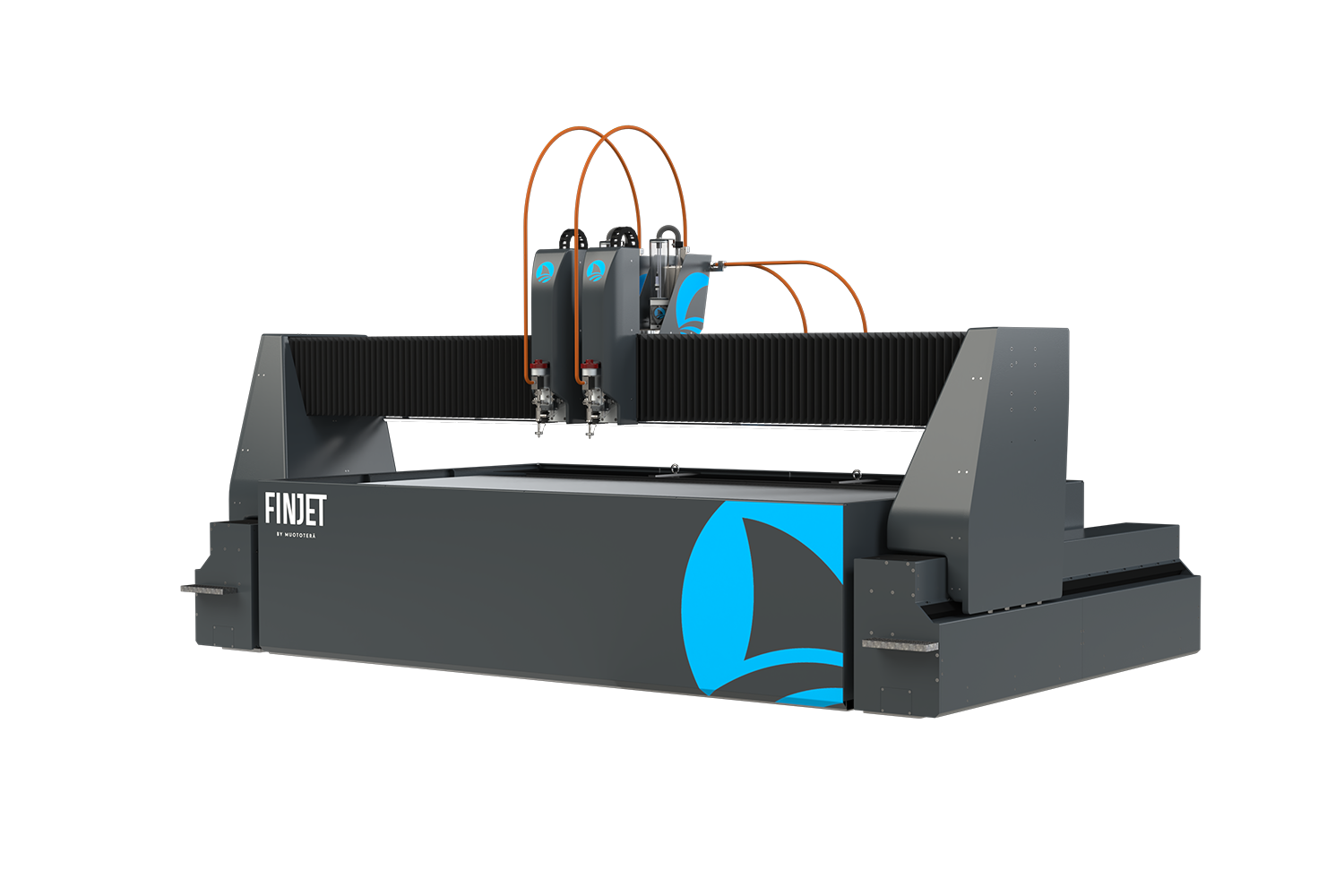

Portal Waterjet cutting machine

Finjet H

Technical specifications

FinJet H-series is designed for continuous heavy duty waterjet cutting. Its modular portal design enables numerous different variations so that every demanding need can be fulfilled. H-series can be equipped with several cutting heads including 5- axis bevel cutting units.

In the FinJet H -series, special attention has been paid to the mechanical solutions of the waterjet cutting machine. The machine is designed to withstand harsh conditions. No matter how dirty, dusty, dark, humid or variable in temperature the environment might be, the FinJet H is designed to function there and provide the comfort you expect from a waterjet cutting machine.

- Cutting area: 1 x 1 – 4 x 15 m

- Z-axis: 200 / 300 mm

- Positioning accuracy: ± 0,025 mm/m

- Repeatability: ± 0,015 mm

- X and Y axis max speed: 15 / 40 m/min

- Cutting heads: 1 – 6, 2D or 3D

In FinJet H models, movement is executed with Ø 30/40 mm precision ball screws, which achieve a movement speed of 15m / min. High-quality B&R (ABB) servomotors are equipped with absolute measurement, which allows the machine to be started without the need for extra reference run. The bearings of the sleds are always mounted on precision guides with four bearings and at sufficient distances to eliminate vibration. The machine’s mechanics are designed for durability and longevity in all conditions.

The movement can also be done by linear motors. This results in higher speeds (40m or even 100m / min) and accelerations

Since abrasive waterjet cutting machines are always exposed to at least abrasive and water, protection must be designed accordingly. In FinJet H models, the X-axis is always protected by a tight round bellows. The Y-movement is protected by a tight rubber lip and the machine frame is covered to withstand extreme conditions.

The machine frame is designed so that it can be walked on, if needed, for easy operation and maintenance.

Electrical and automation design on all FinJet waterjet cutting machines are planned and executed by Muototerä’s own personnel. This allows optimum compatibility between mechanical and automation components. A good waterjet cutting machine is made from quality components, but it is not enough on its own. All parts must work together seamlessly. The objective of Muototerä is always to make the waterjet cutting machines to perform better than the sum of their parts. In practice, this means collaborative design. In other words, mechanical and automation design are executed simultaneously for best results.

Electric cabinets are always built on FinJet H models with closed-circulation cooling, which makes the electrical and automation components more durable and the waterjet cutting machine less prone to failures. The machine is controlled by Muototerä’s own interface for waterjet cutting. The HMI (Human Machine Interface) is a 21.5 ”Full HD touchscreen with a powerful 1.91GHz processor. The user interface has been designed based on the user experience so that it is simple yet powerful, offering all the features needed for effective waterjet cutting.

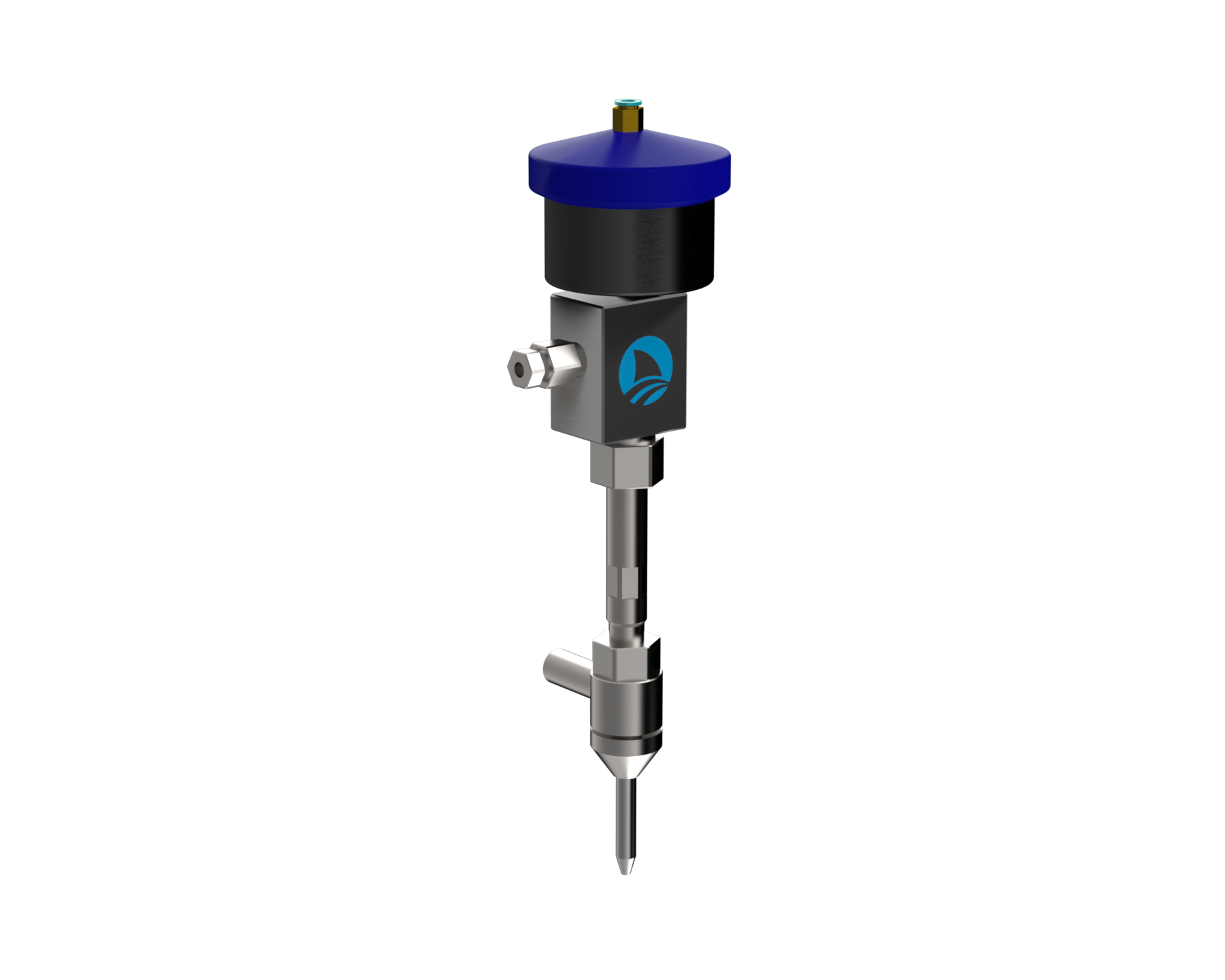

High pressure components play a critical role in waterjet cutting. As it is a high pressure device (3800 – 6200 bar), the high pressure components are subjected to extremely heavy stress. In addition to the self-made components, Muototerä uses components from KMT Waterjet. High-quality components guarantee the reliability of the machine at all pressure levels.

All FinJet waterjet cutting machines can be connected to any high-pressure pump, including old ones already at the client’s site. Muototerä is an official distributor of KMT High Pressure Pumps and a Premium OEM Partner. Our high pressure pump product range can be found here

Finjet H

Available Options & Accessories

From the extensive options list, you can choose the perfect combination of features and accessories to tailor the FinJet H-Portal Waterjet Cutting Machine to your specific needs. Whether you require advanced cutting heads, efficient abrasive management systems, comprehensive reporting possibilities, or enhanced safety features, our customizable options ensure that your machine will deliver optimal performance for your unique applications.

Cutting head

Control & machine

High preassure pump accessories

Abrasive handling

Guns make it easy to clean the plate and parts after cutting.

The sensor in the abrasive feeder monitors the abrasive feed status

Cutting tank

Safety

Applicable Industries

Waterjet cutting solutions for different industrial sectors

The undoubted advantage of waterjet cutting is versatility. The cutting method is suitable for environmentally friendly cutting of almost all materials, such as aluminum, steel, glass, stone, plywood, rubber, plastic, foam and food.

Discover our range of high-performance waterjet cutting machines, engineered for precision, versatility, and reliability. Whether you need to cut metal, stone, or composites, our machines offer tailored solutions to meet diverse industrial needs. With advanced features, robust construction, and user-friendly interfaces, our models are designed to deliver exceptional results and long-term value. Browse through our selection to find the perfect machine for your cutting requirements.

H

Portal Waterjet Cutting Machine

FinJet H-series is designed for continuous heavy duty waterjet cutting. Its modular portal design enables numerous different variations so that every demanding need can be fulfilled. H-series can be equipped with several cutting heads including 5- axis bevel cutting units.

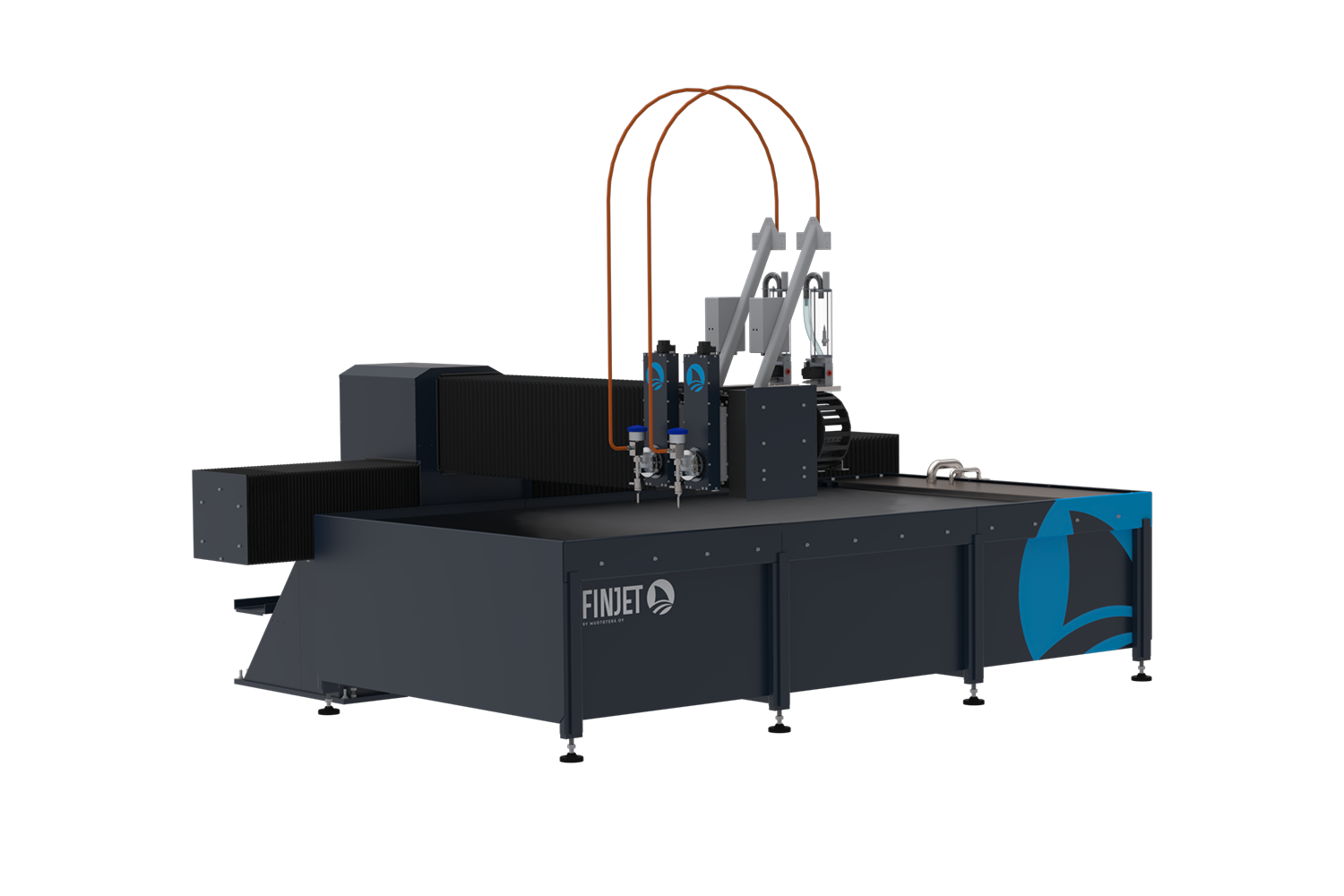

L

Flying Bridge Waterjet Cutting Machine

FinJet L-series is designed for flexible cutting in all environments. Flying bridge design enables the effective use of the machine from three different sides. No matter if you are running a small job shop or producing demanding parts 24/7, with L-series you will be able to correspond all needs of waterjet cutting.

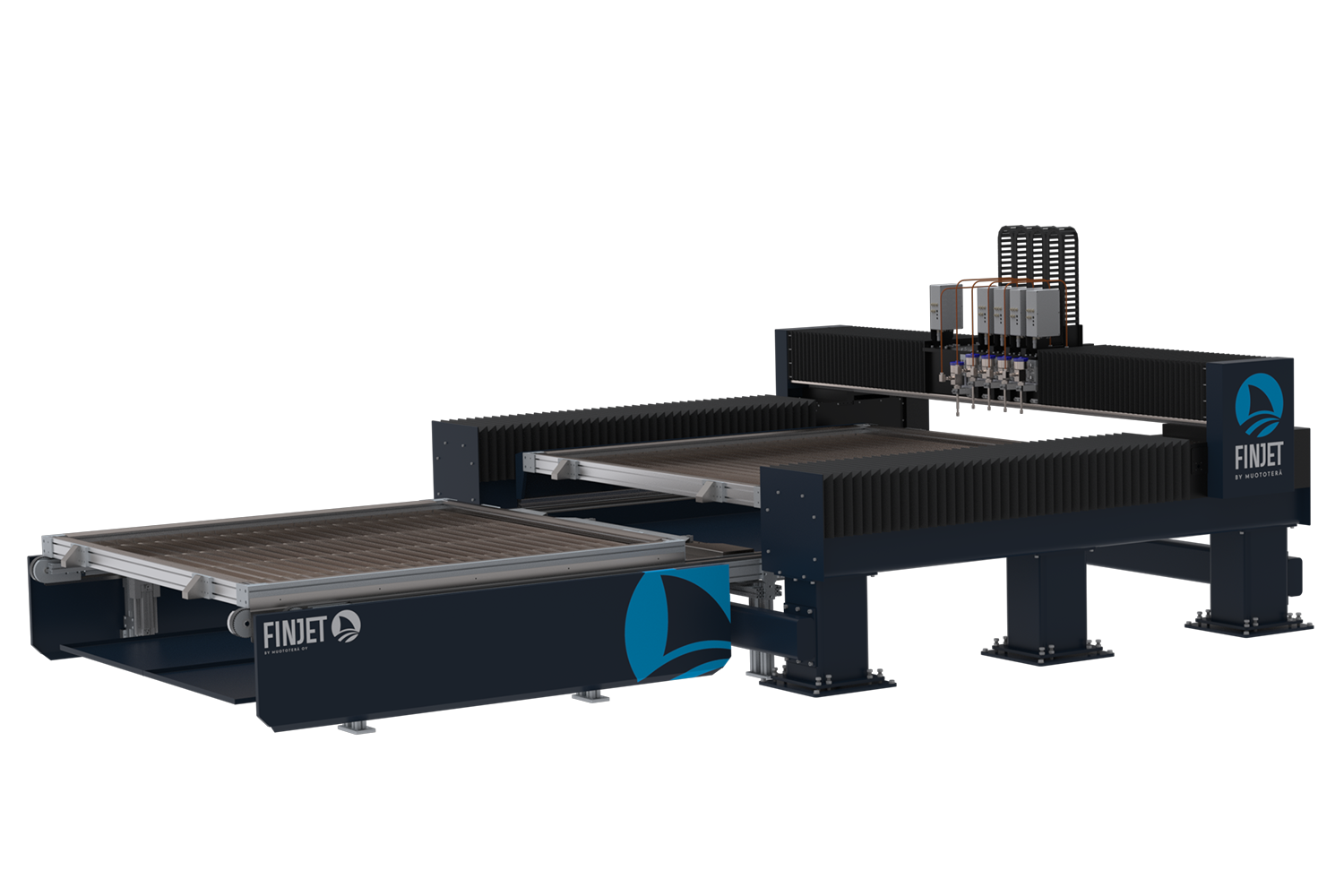

P

Pure Waterjet Cutting Machine

When cutting soft materials, such as plastic, foam, rock wool, rubber or plywood, abrasive can be left out from the cutting process. This enables faster movements and system can be optimized for pure waterjet cutting.

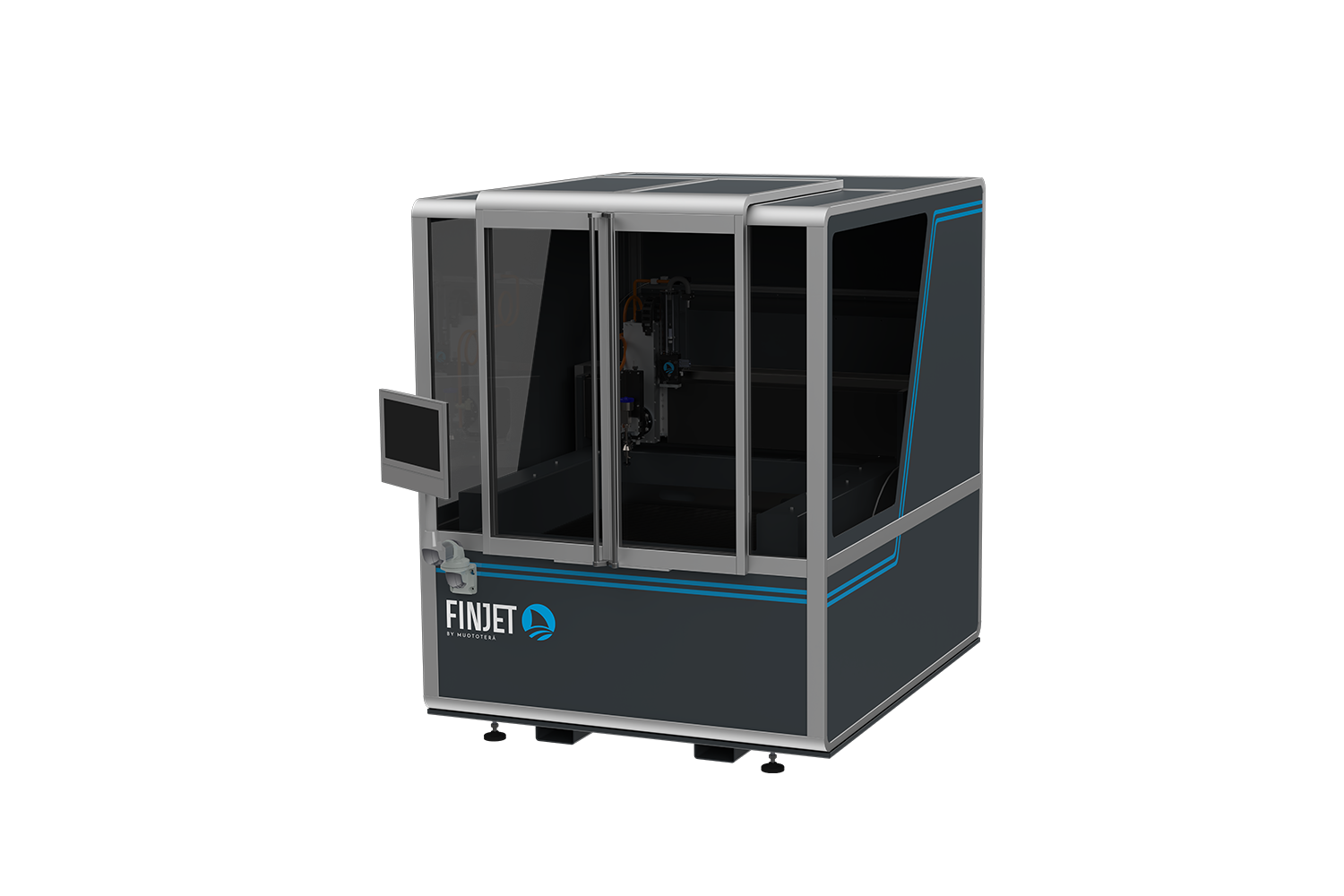

S

Compact & Capsulated Waterjet Cutting Machine

This is a plug-and-play waterjet cutting machine for quick installation and commissioning. Despite its small size, it is a compact waterjet machine for demanding cutting applications, based on the FinJet H Series.

R

Robot Waterjet System

FinJet R-series covers wide range of robot integrated waterjet cutting systems. Waterjet robot is ideal solution when we are aiming for maximum automation of the cutting process. FinJet R series is available for both water-only and abrasive waterjet cutting.

X

Client Customized Cutting System

Sometimes the cutting need is so exotic or demanding that normal waterjet cutting machines cannot offer the best solution. In this case, we make plan how to solve this. FinJet X offers a turnkey package: we plan and offer to solve the problem through the expertise brought by the experience.