Materials

Materials Suitable for Waterjet Cutting

Waterjet cutting technology is incredibly versatile, capable of precisely cutting a wide range of materials without generating heat or causing mechanical stress. This flexibility makes it an ideal solution for various industrial applications.

Materials

Waterjet cutting applications

Muototerä’s FinJet waterjet cutting machines are designed to handle these materials and more, offering precise, clean, and efficient cutting solutions for diverse industrial needs. For more information on how our technology can benefit your specific material cutting requirements, please contact our team.

In principle, everything can be cut with waterjet cutting machine. There are no limitations on the hole size or the material thickness: from small parts up to and over 300 mm thick material can be easily cut. The accuracy can be better than 0,1mm. Kerf , meaning the cutting width, is normally between 0,1 and 1,1 mm, depending on the application. The cutting process itself is easy to learn, the effective nesting software enables the best material use. The maintaining costs are low and with FinJet waterjet cutting machines, you will get a long lasting investment.

Here are some of the key materials that can be effectively cut using waterjet technology:

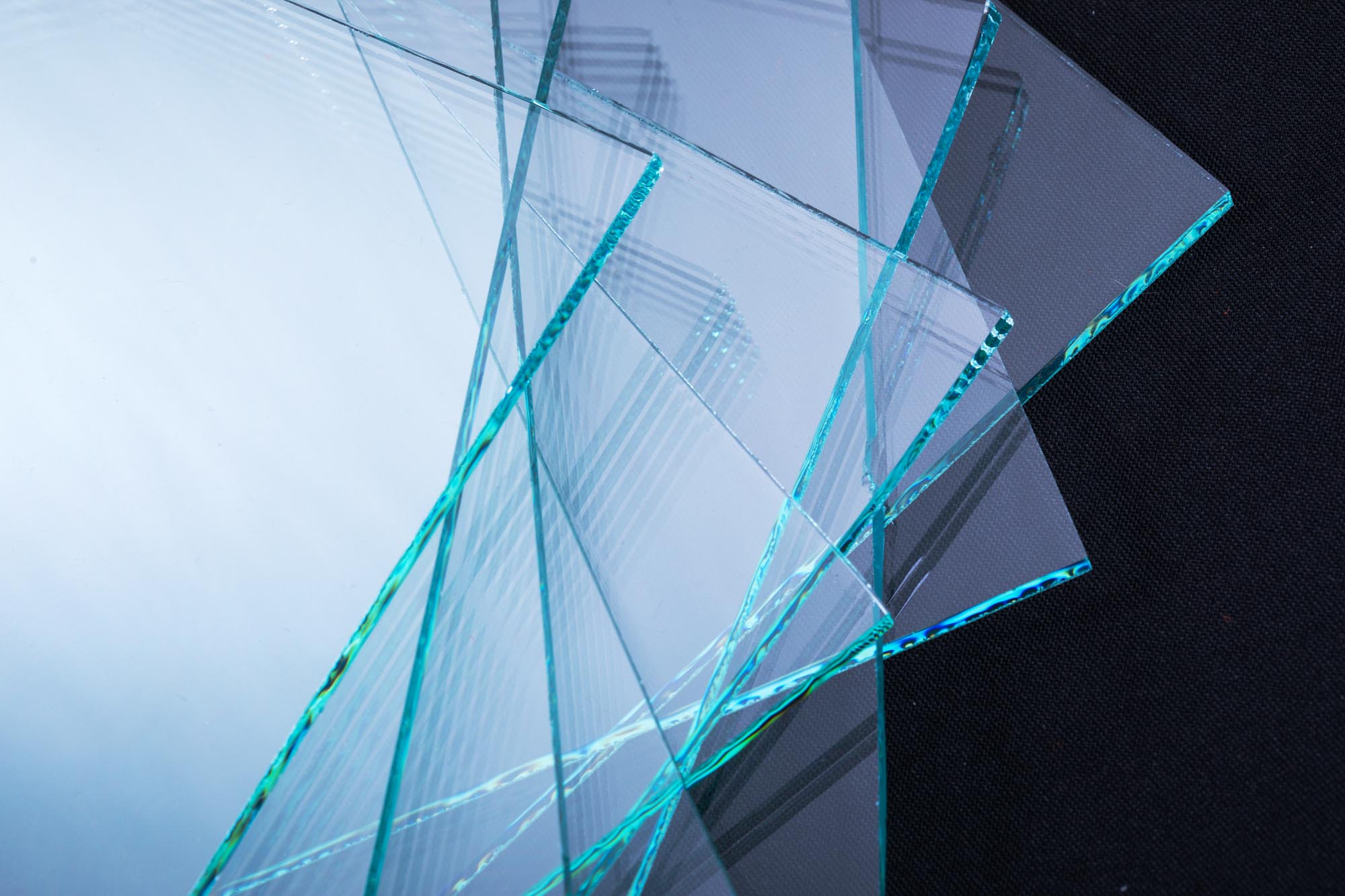

Glass

Abrasive waterjet cutting technology is an optimal method for cutting glass due to its versatility. It allows free form and shape cutting at reasonable cost and without limits. As waterjet cutting is a non-thermal cutting method, there is no heat-affected zones (HAZ). FinJet waterjets enable high-precision glass cutting without scratching or cracking the material. Usually no secondary finishing is required thus improving your production time. The surface resists tampering well after the cutting.

Advantages of cutting glass with water jet

- High quality sharp edges are possible

- Cutting holes and shapes without cracking the material

- Minor loss of material

- No material change due to the cold cutting process

- Damage-free cutting

- High precision without any or with small after-treatment

- No mechanical friction, only the water beam contact the material

Metals

Waterjet cutting is the most versatile method for cutting nearly all kind of metals like aluminum, steel, iron or titanium. With over 30 years of experience in water jet cutting we can provide the optimal results when cutting metals. The 5-axes cutting technology enables practically all shapes and forms, the dynamic cutting technology results a more accurate finished parts. One of the biggest benefit of waterjet cutting is the non-thermal cutting method: the material will not be affected by the heat leaving the surface without burn marks or deformation. Abrasive waterjet easily cut also the toughest materials like titanium or steel.

Advantages of cutting metals with water jet

- Strict tolerance requirements can be achieved

- Minor loss of material due to effective nesting

- Part finishing is often not required: directly finished product from the cutting table

- No material changes due to heat effect

- Sharp angles and burr-free cuts are possible

- Material thickness does not matter, very thin and very thick materials can be cut by waterjet cutting

- Complex shapes are possible with 3D cutting (5-axis cutting)

Stone & tile

Waterjet cutting is a widely used method for cutting stones and tiles. With the right parameters, you can cut holes, edges and more complex models without material deformation, warping or distortion. With abrasive waterjet, cutting of stones and tiles are fast and cost- effective. With the low pressure piercing technology, the material will not crack leaving the surface damage-free. Thanks to the minimal kerf, smooth edges without the need of post-processing is possible.

Advantages of cutting stone and tile with water jet

- Minimal secondary processing

- Warping and distortion can be eliminated

- No thermal deformation

- Cutting complex form, no limitation on edges

- Damage-free cutting

- High quality smooth edges

Wood & paper

One of the biggest benefit of cutting wood with waterjet is the burn-free cutting method which leaves the natural surface of the material without burn-marks or delamination. The waterjet tools are not really wearing out, especially if we use water-only waterjet without abrasives. It enables diverse working possibilities, without changing the tool set. When cutting paper products, cardboard or thin plywood, the high pressurized jet of water is very thin, usually thinner when cutting stones or metals. This enables very accurate and high-precision cutting.

Advantages of cutting wood and paper with water jet

- No chemicals, vapor or smoke produced by the erosion

- Dust and other particles can be filtered out safely from the water

- Stacked cutting is possible, increasing the productivity

- Multiple cutting heads can be used to accelerate the production

- Shuttle table for simultaneous cutting

- Environmentally-friendly cutting solution for sustainable companies

- No delamination or burned marks due to heat affection

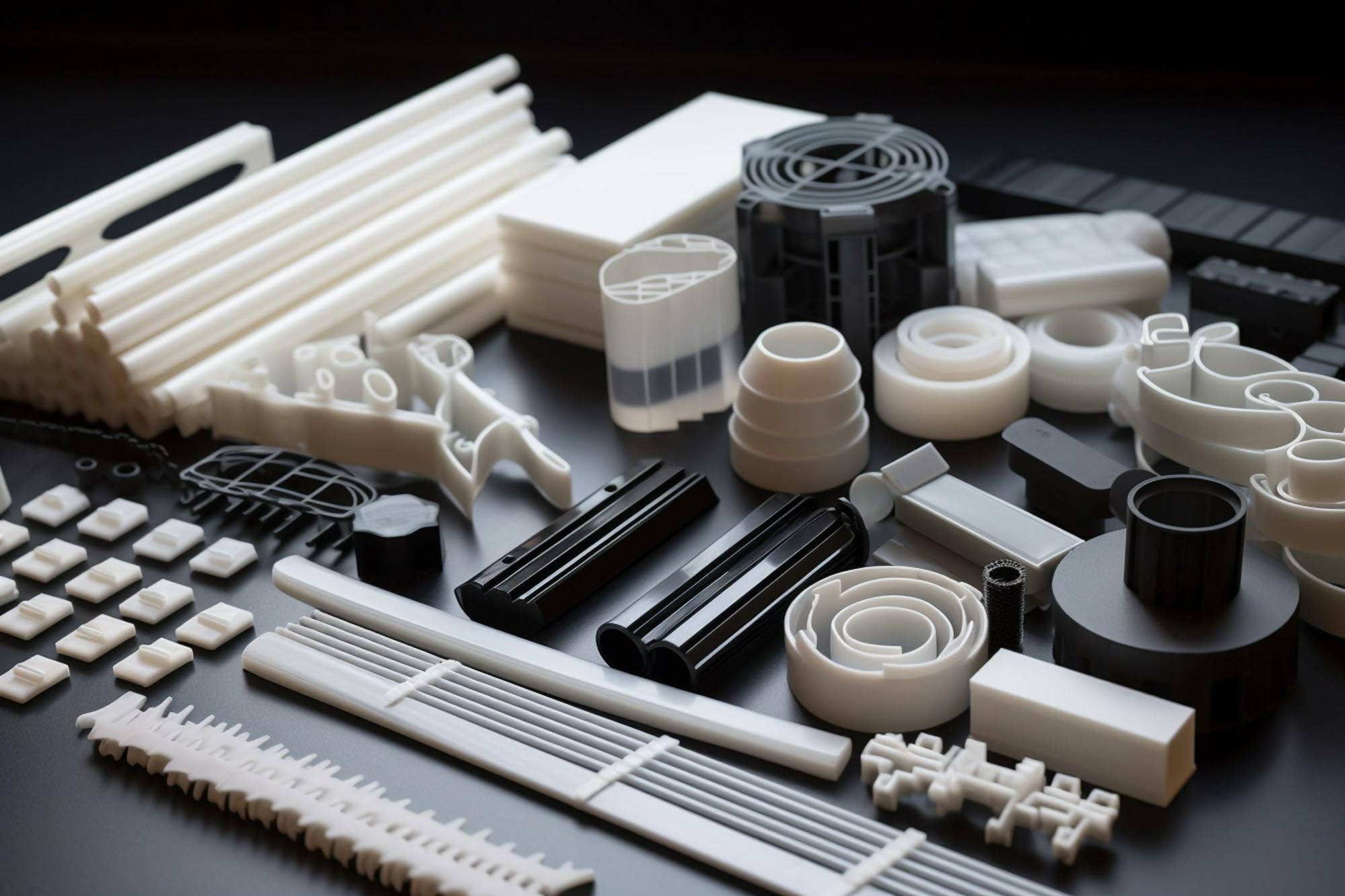

Plastic & rubber

For cutting plastics and rubber with waterjet, you need to specify first the desired cutting quality and thickness of the material to choose the right cutting method which can be either with abrasive or water-only. During the cutting process, there is no structural changes in the material, wide variety of shapes can be cut without changing the tool set. Waterjet cutting is a sustainable cutting solution, no chemicals or harmful gas released from the material during the cutting process. With FinJet waterjet, you can cut multiple pieces with just one run, which saves time and gives a better output for your production.

Advantages of cutting plastic and rubber with water jet

- No harmful gas or chemicals released from the material during the cutting process

- Wide variety of shapes and sizes without changing the cutting tool set

- No thermal deformation

- Possibility to use water-only waterjet for the cutting

- Stacked cutting is possible

- Robot cutting application for more flexible cutting

Other materials

Waterjet cutting is not limited to traditional materials like metals, glass, rubber, stone, tiles, plastics, and wood. Its versatility extends to many other materials, making it a highly adaptable cutting technology for various industrial applications. Here are some additional materials that can be effectively cut using waterjet technology:

Other suitable and widely used materials in waterjet cutting

- Composites

- Ceramics

- Foam

- Textiles

- Food prosucts

- Cardboard

- Leather

- Graphite

- Ceramics

- Kevlar

- Sponges

- Foam core boards

- Polyurethane